Factors to Consider When Installing an Industrial Pump and Motor System

December 1, 2024

Why Energy Efficiency Matters: Oil and Gas Pumps for Sustainable Operations

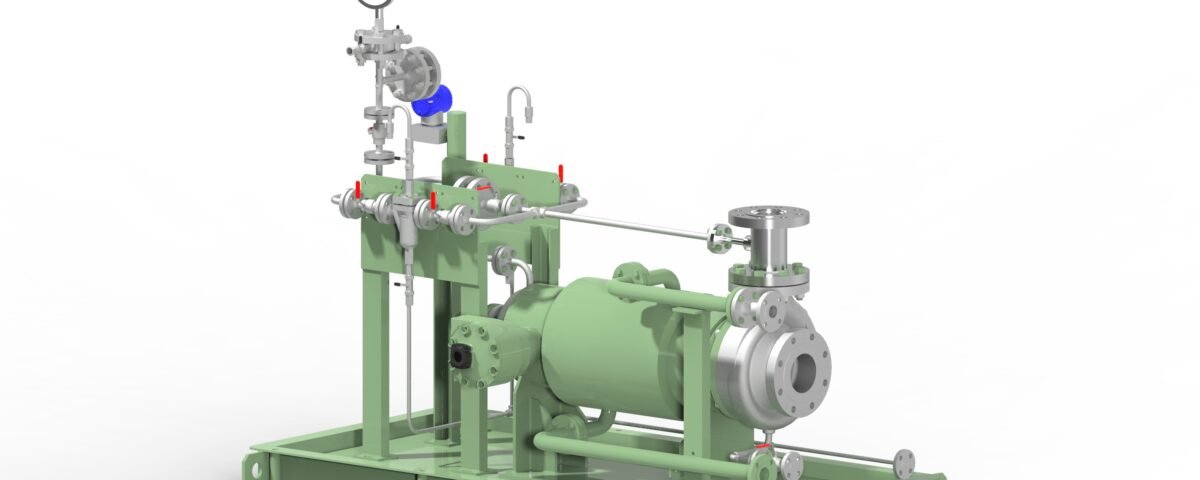

December 27, 2024Reliability and safety cannot be neglected in industrial pumping systems. Canned motor pumps feature an inherently seal-less design and low environmental impact, which is prevalent in critical applications of chemical processing, oil and gas, and power generation industries worldwide. The API 685 standard greatly contributes to improving the performance and reliability of these pumps, with the capability to meet the demanding conditions for hazardous and toxic fluid handling. This blog will discuss why the industry uses API 685 in canned motor pumps and how following this standard benefits the industry.

What is API 685 and Its Necessity

An American Petroleum Institute (API) specification, API 685, is for sealless centrifugal pumps, including canned motor and magnetic drive pumps. It describes rigorous operational and safety requirements for designing and ensuring pumps work at their best in dangerous environments. And you don’t have to give the same pump away when that pays dividends in performance, longevity, and compliance with global safety standards. Hydrodyne Teikoku Pvt. Ltd. follows API 685 in canned motor pump manufacturing and works safely with hazardous fluids, high pressures, and extreme temperatures.

Benefits of API 685 in Canned Motor Pumps

1. Enhanced Safety Features

When dealing with toxic or flammable fluids, safety is paramount. According to API 685, canned motor pumps seek to eliminate the traditional mechanical seal failures that are common in the significant field of pump usage. The seal-less configuration minimises the risk of leaks for workers, equipment and the environment.

API 685 also incorporates advanced monitoring technologies, such as vibration and temperature sensors, that give operators real-time data. It is a proactive approach to safety that detects the abnormalities before they develop into critical issues. These features are indispensable to industries where safety is a non-negotiable thing.

2. Improved Operational Efficiency

As with any line of work, modern industrial applications need efficiency, and API 685 guarantees that canned motor pumps deliver the best results possible. This standard has led to the development of pumps that use hydraulic balance with precision-engineered components, which consume less energy yet produce a higher operational output.

The standard goes on to promote the use of advanced materials that cannot be corroded or worn, thereby minimizing downtime for maintenance. For instance, Hydrodyne Teikoku API 685-compliant pumps utilise the most advanced materials and engineering for ideal performance and are even rugged enough to operate in extreme environments.

3. Extended Equipment Lifespan

Industries that are dependent on uninterrupted operations also rely on longevity. Designed and tested according to stringent design and testing protocols, pumps can take the high pressures, high temperatures, and corrosive fluids dictated by API 685. By focusing on durability, wear and tear becomes minimized, and the operational life of the equipment is maximized.

Engineering design codes specified in API 685 ensure that cooling mechanisms perform consistently without degradation under heavy operational loads on long durations. Inventors and businesses reduce the overall cost of ownership and can rely on long-term performance by investing in API 685 canned motor pump technology.

Technical Features Aligned with API 685

API 685 compliance introduces several technical advancements that enhance the functionality of canned motor pumps:

- Hermetically Sealed Design: It prevents fluid leakage and resists external contaminants to provide a secure operating environment.

- Dual Containment Shells: It is crucial to add an extra layer of safety to make handling hazardous fluids safer if the collagen fails.

- High-Temperature Capability: It safely and efficiently handles fluids at extreme temperatures needed for petrochemicals and power generation industries.

- Advanced Monitoring Systems: Early detection of potential motor winding temperature and flow rate issues is ensured by continuous monitoring of critical parameters.

These features exemplify the innovation and attention to detail that Hydrodyne Teikoku Pvt. Ltd. brings to their API 685-compliant pumps.

Applications of API 685-Compliant Canned Motor Pumps

API 685 in canned motor pumps benefit industries that handle hazardous fluids. Some of the most common applications include:

- Chemical Processing: Handling highly corrosive and toxic chemicals with no leakage and safe and efficient operations. However, the hermetically sealed design is ideal for preventing contamination and maintaining process integrity.

- Oil and Gas: API 685-compliant pumps transport flammable hydrocarbons under high pressure without the risk of leaks in oil refineries and gas processing plants, serving as safer operations.

- Power Generation: High-temperature fluids are circulated using these pumps in the cooling and heating systems and for stable operations in power plants. Because they are so reliable in extreme conditions, they can’t be replaced.

- Pharmaceuticals: API 685 compliant pumps are used for injecting sterile and sensitive fluids with precision, as pharmaceutical manufacturing needs to ensure the fluids remain sterility and specificity suitable.

Why Choose Hydrodyne Teikoku for API 685-Compliant

As an experienced pump manufacturer and industry leader, Hydrodyne Teikoku Pvt. Ltd. is way ahead than others in terms of quality, innovation, and delivering the best to its customers. Our API 685 in canned motor pumps are intended for the most challenging industrial needs, providing exceptional reliability and efficiency.

Hydrodyne Teikoku’s expert team cooperates closely with clients to understand their needs and design ideal solutions to match their expectations. Their comprehensive support spans from consultation service to installation of API 685-compliant pumps into any kind of industrial system.

Conclusion

Canned motor pump technology utilizing the API 685 process has transformed industrial fluid management, delivering unprecedented safety, efficiency, and durability. API 685 compliance is more than regulatory compliance for industries processing hazardous or high-value fluids; it symbolises operational excellence. Regarding API 685 in the canned motor pump, Hydrodyne Teikoku Pvt. Ltd. is a trusted partner with innovative and reliable products to meet your needs. Explore our range of canned motor pumps and experience the benefits of API 685 compliance firsthand. Partner with us to see how we can help improve your operations.