Latest Trends & Innovations in Canned Motor Pump Technology (2026)

February 2, 2026

KOH Pumps in 2026: Applications, Selection Guide, and Maintenance Best Practices

February 2, 2026In industrial fluid handling, the term hermetically sealed canned motor pump is more than engineering jargon. It defines a class of pumps that combine advanced mechanical design, safety-centric operation, and efficiency for demanding environments. As we advance through 2026, the relevance of hermetically sealed canned motor pumps continues to grow across chemical, power, pharmaceutical, nuclear, and downstream process sectors.

At HydrodynePump Teikoku, where we have been pioneering canned motor pumps for over two decades, we see this technology as a cornerstone of modern, leak-free pumping solutions that reduce risk, enhance reliability, and increase operational uptime.

This blog explores what a hermetically sealed canned motor pump is, how it works, its key benefits, and where it’s most effectively applied in industrial systems.

What Is a Hermetically Sealed Canned Motor Pump?

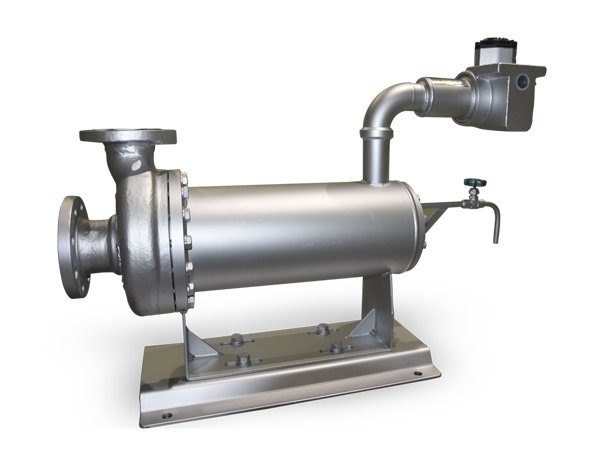

A hermetically sealed canned motor pump is a specialized centrifugal pump in which the motor and pump are integrated into a single, completely sealed unit. Unlike conventional pumps that use mechanical shaft seals connecting the motor to the pump, these pumps have no shaft seal at all. Instead, the rotor and impeller operate within a sealed “can” a containment boundary that isolates the pumped fluid from the motor windings and bearings.

The term hermetically sealed signifies that this sealed boundary is impervious to fluid leakage — even under high pressure or hazardous service conditions. This leak-free design makes hermetically sealed canned motor pumps inherently safe, especially when handling toxic, flammable, or environmentally sensitive fluids.

How Does a Hermetically Sealed Canned Motor Pump Work?

To understand the working principle of a hermetically sealed canned motor pump, it helps to visualize its internal integration:

- Integrated Motor & Pump Assembly

The motor’s rotor is mounted directly on the pump shaft. This eliminates a conventional shaft and seal arrangement. Instead of driving the pump through an external coupling or seals, the motor spins the impeller from within the hermetically sealed enclosure (the “can”). - Sealed Enclosure (“the Can”)

The can is a pressure-resistant containment that surrounds the rotor and stator. Because the pumping fluid itself often fills this enclosure, it acts as a cooling and lubricating medium for the motor components. There’s no direct contact between the fluid and the ambient environment outside. - No Mechanical Seals

The absence of mechanical shaft seals eliminates leakage points. The fluid is sealed within the pump body and can enclosure throughout operation. - Bearings and Motor Cooling

In many designs, fluid from the pump chamber circulates through the can to cool and lubricate bearings and motor windings. This fluid-film lubrication offers excellent reliability compared to grease-filled or externally lubricated systems. - Efficient Stator Cooling

Some hermetic designs use dual containment, where the stator winding is sealed from the fluid while still being cooled by an intermediate fluid circuit. This improves electrical efficiency and protects windings from chemical attack.

Benefits of Hermetically Sealed Canned Motor Pumps

The hermetically sealed canned motor pump offers a range of benefits that make it an ideal choice for many industrial applications particularly in B2B process environments where safety, reliability, and efficiency are priorities.

1. Zero Leak Operation

The most fundamental benefit is the elimination of shaft seals — the most common failure point in conventional pumps. With no mechanical seals, hermetically sealed canned motor pumps deliver virtually zero leak risk, even when handling hazardous, toxic, or high-pressure fluids.

This dramatically enhances worker safety, environmental compliance, and equipment integrity.

2. Enhanced Safety & Compliance

In sectors such as chemical processing, petrochemicals, and pharmaceuticals, regulatory standards (like OSHA, EPA, and global equivalents) demand strict fluid containment. Hermetically sealed designs help businesses meet these standards with a pump that is intrinsically safe by design.

3. Reduced Maintenance & Downtime

Mechanical seals require regular inspection, lubrication, adjustment, and replacement. With no seals to service, canned motor pumps significantly reduce maintenance frequency and associated labor costs. The sealed design also minimizes contamination risk and enhances operational continuity.

4. Improved Reliability in Harsh Conditions

Hermetically sealed pumps excel where conventional pumps struggle — high pressures, high temperatures, corrosive fluids, and flammable environments. The integrated design protects internal components from external contaminants and ensures consistent performance.

5. Operational Efficiency

The direct integration of motor and pump allows for fewer moving parts, lower frictional losses, and more compact footprint. Combined with the enhanced cooling provided by the pumped fluid itself, hermetically sealed canned motor pumps often provide superior energy efficiency compared to traditional sealed pumps.

Key Industrial Applications

Because of their safety and reliability advantages, hermetically sealed canned motor pumps are widely used across strategic industrial sectors where leaks are unacceptable and reliability is critical.

Chemical Processing

Handling corrosive, toxic, or volatile chemicals demands leak-free operation. Hermetically sealed canned motor pumps transfer acids, solvents, and specialty chemicals without risking environmental exposure or plant safety.

Petrochemical & Refining

In refining and petrochemical plants, these pumps handle hydrocarbons, hydrogen, and other high-value fluids. Their sealed design reduces fire and explosion risk while maintaining process purity.

Pharmaceutical Manufacturing

Clean-in-place (CIP) and sterile production environments benefit from hermetically sealed pumps that eliminate contamination risk and support strict hygiene standards.

Power Generation & Utilities

From boiler feed to cooling circuits and chemical dosing systems, power plants rely on robust pumping solutions that operate continuously and safely under variable conditions.

Nuclear & High-Safety Environments

In environments where risk tolerance is nearly zero, hermetically sealed canned motor pumps provide the leak-proof assurance required for both safety and regulatory compliance.

2026 Update: Trends Driving Adoption

As we move deeper into 2026, several trends are accelerating the adoption of hermetically sealed canned motor pumps:

- Digital Monitoring & Predictive Diagnostics — Integration with IoT and asset-management systems improves uptime.

- Advanced Materials — Corrosion-resistant alloys and coatings expand operating envelopes.

- Sustainability Requirements — Leak elimination supports tighter environmental regulations and corporate sustainability goals.

- Lifecycle Cost Optimization — Long service life and low maintenance reduce total cost of ownership.

Conclusion

A hermetically sealed canned motor pump represents a significant engineering advantage in industrial fluid handling. By eliminating mechanical seals, integrating motor and pump, and ensuring a fully sealed fluid containment, this technology prioritizes safety, reliability, and efficiency exactly the qualities that modern process industries demand.

At HydrodynePump Teikoku, our deep expertise in canned motor pump manufacturing enables us to deliver hermetically sealed solutions tailored to critical applications helping our B2B partners operate safely, sustainably, and with optimal performance.