The Importance of Regular Maintenance for Canned Motor Pumps

May 2, 2024

Tips To Choose The Right Canned Motor Pump

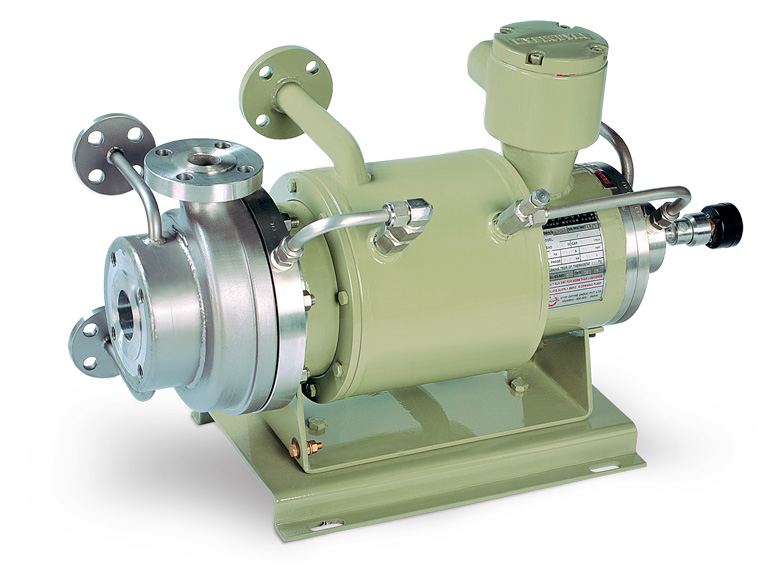

June 5, 2024Moving fluids from one place to another can be a daunting task but one can perform this activity with ease by using motor pumps. Not just fluids but slurry, solids, powders, etc, are also moved using these pumps. Hydrodyne Teikoku Canned Motor Pumps, which provide a safe and steady fluid movement, are helpful in handling hazardous and toxic fluids.

In industries like Chemicals, Petrochemicals, and Nuclear Power, the movement of fluids are of prime importance and must be out of harm’s way. Thus, Hydrodyne canned motor pumps are used in these types of industries to ensure complete safety. API 685 standards are specialized in these industries to guarantee containment and prevent leakage risk. In this blog, the significance of API 685 in Hydrodyne Teikoku canned motor pumps application will be explained thoroughly.

What are API 685 Canned Motor Pumps?

API 685 is nothing but a standard mark that states that the movement of hazardous or toxic fluids through the pumps will be completely safe and secure. The API 685 i.e the rules from the American Petroleum Institute originated in the year 2001 for maintaining and ensuring safe sealless centrifugal pumps, designed to cater petroleum, pharmaceuticals, Oil and Gas industries, etc.

API 685 acts as a hallmark for the above-mentioned heavy-duty industries as for them safety and security is priority. The standard describes that the pumps are designed, built, and tested to work accurately and safely.

Benefits of API 685 for Canned Motor Pumps

-

Leak Prevention:

As designed according to API 685 standards, the canned motor pumps remain sealless. The main advantage of these sealless motor pumps is that they provide total protection from leakage. Fluids that can be harmful or cause environmental issues require proper solutions, and API 685 pumps provide sealless, leakage-prevention quality.

-

Robust Materials:

Robust means immense strength that can manage and handle errors efficiently. API 685 uses robust materials to promise its clients or consumers the overall safety of the pumping system. The canned motor pumps under API 685 standards have some vigorous and high-quality materials that help them carry and hold dangerous fluids safely into the pumps.

-

Lower Maintenance Cost:

Canned Motor Pumps of API 685 standards possess low maintenance cost as there are no mechanical seals and fewer technical components. Due to this, the repair cost are also saved, ultimately reducing the overall maintenance cost of the pumps. As the pumps under the standards are rigorous, there are less chances of damage, and can easily recover if any failure or errors arrive.

-

Zero Emissions:

With complete leakage prevention, canned motor pumps provide you with complete assurance of environment protection. The harmful gasses or fluids that are held in these pumps are safely stored and transferred and thus our environment remains protected from the harmful emissions. Therefore, it has become a necessity for the industries dealing with toxic contents that can damage the environment in one or other way.

-

Operation efficiency:

The API 685 mark standards are given to the pumps after complete examination. Proper and strict testing is done to ensure that the work goes swiftly and smoothly. Operational efficiency leads to higher productivity and improved profit for any company. The standard is also responsible for monitoring the canned motor pumps operations to inform its users about potential complications.

-

Durability:

Due to the numerous benefits, such as leak prevention, robust materials for ensuring the safety of dangerous and toxic liquids, and protection of the environment, API 685 pumps are completely durable. Every company wants to have high-quality material with lower maintenance costs, and thus, they use API 685 canned motor pumps for a more extended period of time.

Conclusion:

Are you concerned about the breaking down of pumps and emissions of harmful gas into the environment? No worries! Hydrodyne Teikoku Pumps comes up with API 685 standards that provide you with one of the best Canned Motor Pumps (CMPs) to guarantee reliability and efficiency.

Due to consistent testing and high-quality materials, toxic gases or fluids handling in heavy-duty industries is assured. The API 685 canned motor pumps are well-known for operating within environmental regulations, and that’s what makes them safe and compliant. Explore a variety of Hydrodyne Teikoku canned motor pumps, which perform reliably at several facilities.