Top Applications of Sealless Canned Pumps in Various Industries

August 22, 2024

Key Benefits of Using Leak-Free Pumps in Industrial Applications

August 22, 2024When choosing the best Seal-Free pump, it is essential to know what you need. Seal-Free Pumps have many advantages. They work with fluids without conventional seals, which may deteriorate and develop faults over time, causing leakage. These pumps are suitable for use in industries where leak-free conditions and handling aggressive or hazardous fluids are paramount.

Understanding Seal-Free Pumps

They are designed to run without mechanical seals and are usually mounted in conventional pumps to minimize fluid loss through the shaft. However, such pumps use magnetic drive or canned motors to convey power, and there is no likelihood of leakage. This makes them suitable for use in areas that involve safety issues, environmental conservation, and overall system maintenance costs.

Types of Seal Free Pumps

Seal-Free Pumps are available in different variants, each used for particularly suitable purposes in various industries. It will be beneficial for you to understand the severe types of pumps to identify your requirements:

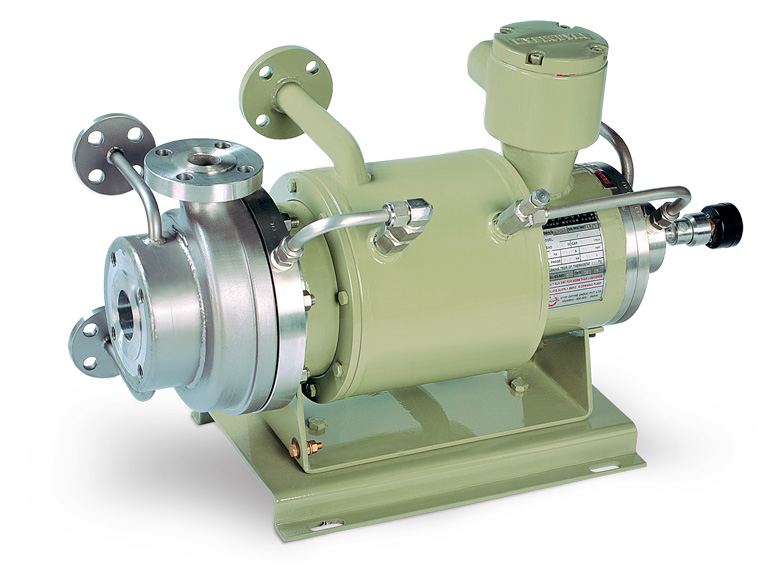

- Magnetic Drive Pumps: These pumps don’t have mechanical transmission between the motor and the pump impeller, they use magnetic coupling for functioning. This design does not have seals and works best when dealing with challenging chemicals and ultrapure fluids.

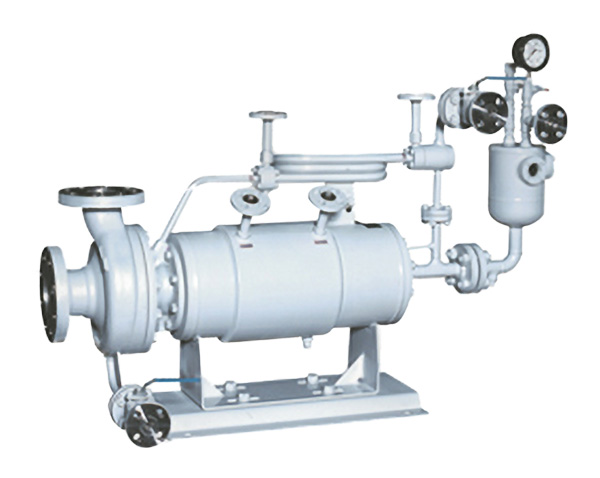

- Canned Motor Pumps: Canned motor pumps combine the motor and the pump into one assembly that is enclosed in a housing. The motor is fully enclosed, making these pumps almost wholly leakproof. They can be employed where total exclusion of the fluid the pump conveys is desirable.

- Peristaltic Pumps: These are not generally classified as Seal-Free; peristaltic pumps derived their acquaintance through being Seal-Free, using a hose to transport the fluid. These pumps are particularly suitable for pumping thick, gritty, or fragile fluids and are used widely in the food processing, pharmaceutical, and chemical industries.

Benefits of Seal-Free Pumps

- Leak Prevention: The first benefit of Seal-Free pumps is the absence of leaks. Tightly sealed traditional pumps can also stop working, leading to leakage that may be very expensive and pose some risks where dangerous substances are involved in the process. Seal-Free pumps do not possess this risk; therefore, they offer safer and more effective operation.

- Reduced Maintenance: Seal-Free pumps are built without seals and, therefore, do not require frequent maintenance. Because there is no need for seals, which would necessitate replacements, these service needs are greatly minimized. Apart from saving time and labour, this reduces the time taken to attend to faults, thus enhancing the efficiency of the machines.

- Handling Hazardous and Corrosive Fluids: Seal-Free pumps are most applicable when the fluids being pumped are corrosive or hazardous. Since there are no seals, fewer parts are exposed to these fluids that could damage the pump, which gives the pump a long life and reliability.

- Environmental Benefits: Seal-Free pumps do not allow fluid leakage, which means that they cannot contaminate the environment with dangerous materials. As such, they are suitable for industries with high regulations on their impacts on the physical environment and emission of greenhouse gasses.

Choosing the Right Pump for Your Needs

When selecting a Seal-Free pump, consider the following factors:

- Fluid Characteristics: Identify and know the fluid that must be pumped. Is it capable of corroding and emitting hazardous fumes, or is it highly viscous? The specific type of fluids that a Seal-Free pump deals with may require using that pump and not some other Seal-Free pump.

- Flow Rate and Pressure: Know the flow rate needed and the pressure that must be established in your case. Ensure the chosen pump can meet these requirements without straining its performance.

- Operating Environment: The environmental conditions under which the pump will be working should also be considered. These include temperature, exposure to chemicals, and risk of contamination, which should influence your decision.

- Maintenance and Operational Costs: Seal-Free pumps are often said to be low maintenance, but the difference must be viewed in terms of cost bearings, including energy consumption in the long run, cost of manufacture, and reliability.

Also Read:- Reasons To Use Canned Motor Pumps In Chemical Industry

Conclusion

There are many uses for Seal-Free pumps because of their advantages, such as complete protection from leaks, the need for minimal services and the capacity to manage hostile and abrasive fluids. When, in the next part, you understand your requirements and the types of sealless pumps, you can make the right decision geared towards safety, efficiency and reliability in operations. From chemical pharmaceuticals to any sector where leakage is not permissible with your pumping, you must get it right with the Seal Free Pump.