Is Your Leak-Free Pump Really Leak-Free? Essential Maintenance Tips

August 13, 2024

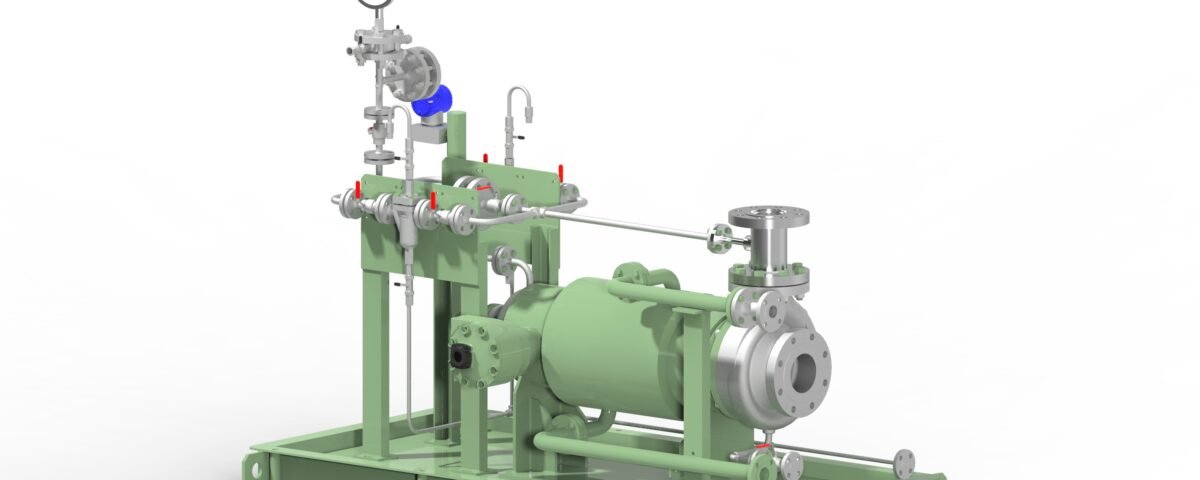

Ultimate Guide to Emission Free Pumps: Technology, Benefits, and Applications

August 20, 2024The selection process for the Canned Motor Pump Manufacturer is vital in any industrial process. Canned motor pumps are essential for the transportation of hazardous, corrosive, or high-temperature fluids without leakage, making their application in the chemical processing, oil and gas, and pharmaceutical industries compulsory.

To get the highest performance and durability, you should deal with a reliable manufacturer with appropriate experience. In India, Hydrodyne Teikoku India Pvt. Ltd. comes forward to serve you with the expertise of two decades in manufacturing canned motor pumps. Their every product is manufactured using the latest technology and standardisation.

1. Assess the Manufacturer’s Experience and Reputation

When choosing a canned motor pump firm, the first step many people take is to consider the experience of that company. Only some manufacturers with experience in developing excellent quality pumps can provide you with satisfactory pumps for your industrial use. Search for producers with expertise in the particular sector where you operate because it increases the possibility that the firm grasps the specific hardships of the industry as well as the accepted norms.

2. Evaluate Product Range and Customization Options

Canned motor pumps are used in many industries, and as such, their demands differ from one sector to another. It could be difficult for a manufacturer specialising in only pumps to meet all your needs. Therefore, a manufacturer with a diverse portfolio will likely have a pump that meets your needs. This applies to such specifics as a need to pump highly corrosive fluids or work in conditions of very low or elevated temperatures.

Think about whether you want some specific features offered by this manufacturer. Speciality pumps may be needed for industrial usage due to differences in the type of material used, the construction of the pump, or the flow rate ability of the pump. A manufacturer is likely to know precisely your requirements if you hire the services of a specialized provider of custom-made pumps, and this assures the manufacturer that the pump has been optimized for performance and durability.

3. Check for Compliance with Industry Standards

You would agree that standards are critically important when it comes to industrial pumps. Ensure the manufacturer complies with standardisations like API-685, ISO-9000, and ANSI. Observing these standards ensures that the pumps are lasting, safe, and up to the highest standards.

Inquire about the manufacturer’s quality control processes. A manufacturer that employs rigorous testing and quality assurance procedures is more likely to deliver durable and efficient pumps. One of India’s leading Canned Motor Pump Manufacturers and suppliers that provide top-grade and certified leak-free pumps is Hydrodyne Teitkoku India Pvt. Ltd. They have been manufacturing leak-free pumps for the past two decades and have served various industries.

4. Consider the Manufacturer’s Technical Support and After-Sales Service

Technical support and after-sales service are critical in a company dealing with complex industrial equipment like canned motor pumps. Seek to buy from a manufacturer offering support, from installation assistance and maintenance services to troubleshooting. All this support will ensure that your pump works efficiently and that any issues are promptly resolved to minimize downtime and operational disruption.

Canned motor pump manufacturers that make spares readily available and execute periodic checks for maintenance and performance upgrades help extend the life of any pump while keeping it at peak performance.

5. Evaluate the Manufacturer’s Global Reach and Delivery Capabilities

Industrial operations demand that equipment be available at the right time. Delays in equipment delivery result in expensive downtime and project setbacks. Therefore, it becomes necessary to select a reliable manufacturer for delivery performance. Manufacturers with a global reach and well-established logistics networks are better positioned to deliver products on time, no matter your location.

6. Review Cost-Effectiveness and Long-Term Value

Cost alone may be a large driver, but the long-term value of a pump is, in many instances, more important than the purchase or installation value. Decent canned motor pumps may have a high purchase price, but most often, they are way more efficient in operations, have an extended life, and consequently, because of a low failure rate, lower total cost of ownership. Align the manufacturer’s pricing with the quality and robustness of their pumps to provide value for your investment.

Conclusion

The proper Canned Motor Pump Manufacturer would be the one that can match up to experience, product range, industry standards, technical support, delivery capabilities, and cost-effectiveness. Significant consideration of all these factors will undoubtedly be of great use in choosing a manufacturer that will not only serve the current needs but also foster the long-term enterprise industrially.