KOH Pumps in 2026: Applications, Selection Guide, and Maintenance Best Practices

February 2, 2026

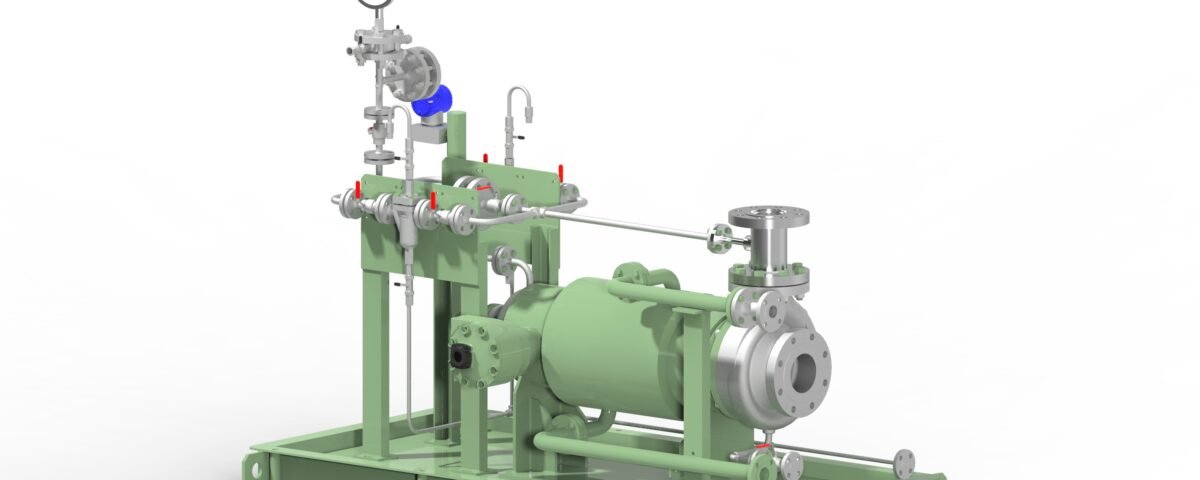

Selecting Canned Motor Pumps for Demanding Solar Thermal Power Plant Conditions

February 26, 2026As industrial processes evolve, operating temperatures continue to rise across sectors such as chemicals, energy, petrochemicals, and power generation. In 2026, the demand for reliable high temperature pump solutions has become more critical than ever, driven by the need for continuous operation, enhanced safety, and reduced lifecycle costs.

At HydrodynePump Teikoku, with over two decades of expertise in engineered canned motor pumps, we understand that high-temperature fluid handling is not just a mechanical challenge. It requires precise engineering, advanced material selection, and a deep understanding of process conditions. This blog explores where high temperature pumps are used, what materials make them reliable, and how industries can select the right pump for long-term performance.

What Defines a High Temperature Pump?

A high temperature pump is designed to handle fluids operating well beyond standard ambient conditions, often ranging from 200°C to over 400°C, depending on application and fluid type. These pumps must withstand not only elevated temperatures but also thermal cycling, pressure fluctuations, and aggressive chemical environments.

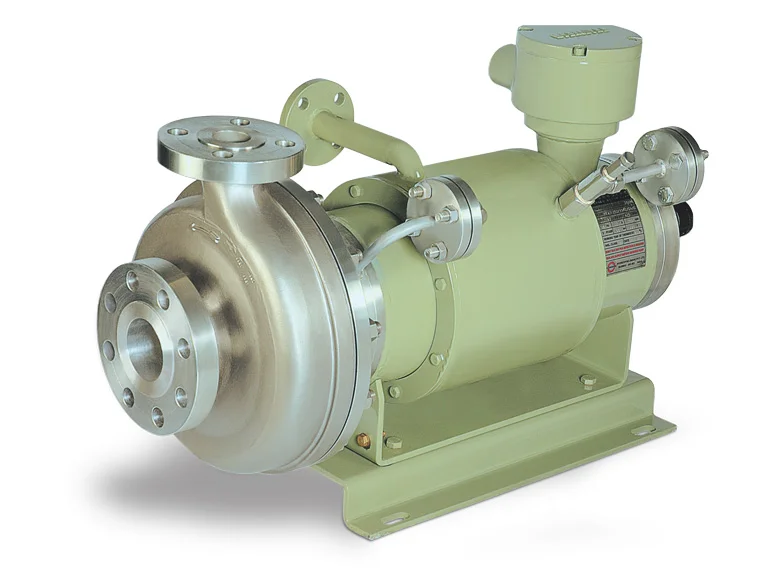

Traditional pump designs often struggle under such conditions due to seal degradation, material fatigue, and bearing failure. As a result, seal-less designs, particularly canned motor pumps, are increasingly preferred for high temperature applications due to their inherent reliability and safety.

Key Applications of High Temperature Pumps in 2026

High temperature pumps play a vital role across multiple industrial sectors where process stability and safety are paramount.

Chemical & Petrochemical Processing

Many chemical reactions and heat transfer processes require fluids to be pumped at elevated temperatures. High temperature pumps are commonly used for hot oils, heat transfer fluids, aggressive chemicals, and intermediate products where leakage could pose safety and environmental risks.

Power Generation

In thermal power plants, high temperature pumps are essential for circulating boiler feedwater, condensate, and heat transfer media. Reliability is critical, as pump failure can lead to costly plant shutdowns and safety hazards.

Oil & Gas Refining

Refineries rely on high temperature pumps to move hydrocarbons, thermal oils, and process fluids under extreme conditions. These applications demand pumps that can operate continuously without seal failure or performance degradation.

Polymer & Plastics Manufacturing

Polymer processing often involves molten or semi-molten fluids that must be transferred at high temperatures. Pumps used in these applications must resist thermal expansion, maintain dimensional stability, and deliver consistent flow.

Renewable & Thermal Energy Systems

Concentrated solar power plants and thermal energy storage systems increasingly rely on high temperature pumps to circulate molten salts or specialized heat transfer fluids efficiently and safely.

Materials That Enable High Temperature Performance

Material selection is the backbone of any reliable high temperature pump. In 2026, manufacturers focus on advanced alloys and engineered materials that maintain strength, corrosion resistance, and dimensional stability under heat stress.

High-Grade Stainless Steels & Alloys

Austenitic stainless steels, duplex steels, and nickel-based alloys are widely used for pump casings, impellers, and shafts due to their resistance to oxidation, corrosion, and thermal fatigue.

Specialized Bearings & Bushings

Bearings used in high temperature pumps must tolerate heat while maintaining low friction. Carbon, silicon carbide, and other engineered ceramic materials are commonly used to ensure durability and stable operation.

Thermal-Resistant Insulation & Can Materials

In canned motor high temperature pumps, the can and stator insulation must withstand prolonged exposure to elevated temperatures without electrical breakdown or deformation.

Advanced Coatings

Protective coatings enhance resistance to corrosion, erosion, and chemical attack, extending service life in harsh, high-temperature environments.

High Temperature Pump Selection Guide

Choosing the right high temperature pump requires a holistic evaluation of operating conditions and process requirements.

1. Define Operating Temperature & Fluid Properties

Accurate temperature range, viscosity, pressure, and chemical composition of the fluid must be clearly defined. These factors directly influence material selection and pump design.

2. Prioritize Seal-less Designs

Mechanical seals are often the weakest point in high temperature applications. Seal-less high temperature pump designs, such as canned motor pumps, eliminate leakage risks and reduce maintenance demands.

3. Consider Thermal Expansion & System Design

Pumps must be engineered to accommodate thermal expansion without misalignment or internal stress. Proper system integration, including piping flexibility and insulation, is equally important.

4. Evaluate Cooling & Lubrication Methods

High temperature pumps rely on efficient cooling strategies to protect bearings and motor components. In canned motor pumps, the process fluid often serves this role, making flow management critical.

5. Focus on Lifecycle Cost, Not Just Purchase Price

In 2026, industrial buyers increasingly evaluate pumps based on total cost of ownership. A robust high temperature pump with minimal downtime and lower maintenance costs delivers superior long-term value.

Why High Temperature Pumps Are Strategic Assets

High temperature pumps are no longer just auxiliary equipment. They are strategic assets that directly impact plant safety, energy efficiency, and operational continuity. Failures in high-temperature systems can result in severe downtime, safety incidents, and financial loss.

At HydrodynePump Teikoku, our high temperature canned motor pump solutions are engineered to meet these challenges head-on. By combining advanced materials, seal-less design, and application-specific engineering, we help industries operate confidently under extreme thermal conditions.

Conclusion

As industrial processes continue to push thermal limits, the importance of selecting the right high temperature pump cannot be overstated. In 2026, success depends on more than just temperature ratings; it requires intelligent design, proven materials, and a deep understanding of real-world operating conditions.

With HydrodynePump Teikoku’s experience and commitment to engineering excellence, industries can rely on high temperature pump solutions that deliver safety, efficiency, and long-term performance in the most demanding environments.