Best Liquid Refrigerant Pumps & Parts for Industrial Applications

September 25, 2025

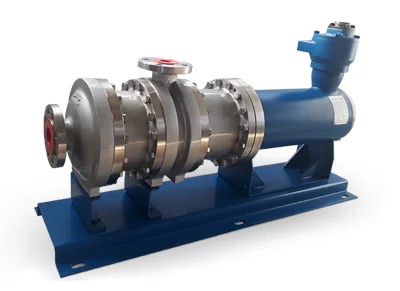

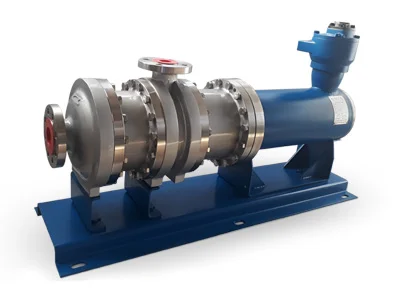

Key Facts About the LPA Liquid Refrigerant Pump

September 25, 2025In industrial operations, the importance of reliable pumping systems cannot be overstated. From chemical plants to power generation units, petrochemical facilities, pharmaceuticals, and industrial cooling systems, liquids must be moved efficiently, safely, and at the correct pressure. Even a small failure or leak in a pumping system can halt production, create hazards, or result in significant financial loss.

This is precisely where multistage pumps excel. Engineered for high-pressure, low-flow applications, these pumps are designed to provide consistent, leak-free performance while optimising energy use and minimising maintenance.

Unlike conventional single-stage pumps, multistage pumps utilise multiple impellers in series, which allows them to gradually increase the liquid’s pressure in stages. This design makes them ideal for applications where high head and reliable pressure delivery are required, without overburdening the motor or other system components.

In this blog, we will take a comprehensive look at the multistage pumps, including how they work, their components, key features, applications across industries, and why they are considered a dependable choice for high-pressure fluid handling.

Understanding Multistage Pumps

A multistage pump is a centrifugal pump in which the liquid passes through multiple impellers connected in series. Each impeller increases the pressure slightly, and the liquid is guided from one impeller to the next through carefully engineered pump casings. By the time the fluid reaches the discharge point, it has accumulated enough pressure to meet demanding operational requirements.

Think of it like climbing a series of steps: each step raises the liquid a little higher, and by the top, it has reached the height or pressure needed.

These pumps are particularly suitable for high-head, low-flow applications, common in industries where precision, reliability, and safety are critical.

How Hydrodyne Teikoku Multistage Pumps Work

The working principle of Hydrodyne Teikoku multistage pumps is simple but highly effective:

- Suction Stage: Liquid enters the pump through the suction inlet, drawn in by the first impeller.

- Stage-by-Stage Pressure Increase: The first impeller imparts initial pressure, and the liquid flows through a diffuser or casing to the next impeller.

- Cascading Pressure Build-Up: Each impeller in succession increases the liquid’s pressure incrementally.

- Discharge Stage: After passing through all stages, the liquid exits at the required high pressure, ready to be delivered to long pipelines, tall tanks, or high-pressure systems.

This method allows for efficient high-pressure generation without requiring a very large single impeller or motor, making the pump energy-efficient and compact.

Key Components of Hydrodyne Teikoku Multistage Pumps

Each part of a Hydrodyne Teikoku multistage pump is engineered for durability and reliable operation:

- Impellers: Multiple impellers arranged in series, each increasing the pressure slightly.

- Pump Casing: Guides fluid between impellers and protects internal components.

- Shafts and Bearings: Ensure smooth rotation, handle high axial loads, and maintain alignment.

- Mechanical Seals: Prevent leakage where shafts enter the casing.

- Labyrinth Seals: Non-contact sealing to block fluid escape, ideal for sensitive liquids.

- Thrust Collars & Rotor Assemblies: Maintain shaft alignment and absorb axial forces.

- Diffusers: Direct the flow efficiently from one impeller to the next to minimise energy loss.

Understanding these components helps operators appreciate the precision engineering that goes into every Hydrodyne Teikoku pump.

Features and Benefits of Hydrodyne Teikoku Multistage Pumps

Hydrodyne Teikoku multistage pumps are packed with features that address key industrial challenges:

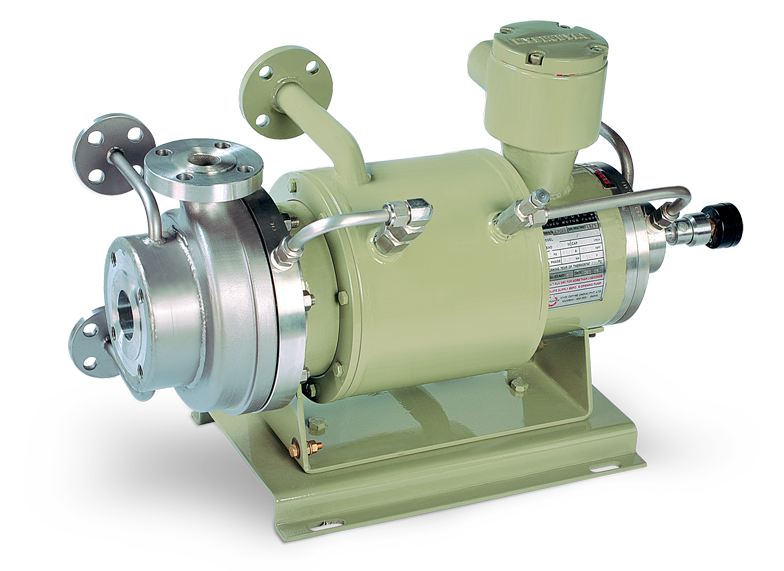

Complete Leak-Free Operation

The hermetic design eliminates mechanical seals, meaning the pumped liquid cannot escape. This makes the pumps ideal for:

- Harmful or toxic fluids

- Explosive or flammable liquids

- Expensive chemicals

- Corrosive substances

Leak-free operation improves safety, compliance, and environmental protection, which are vital in regulated industries.

No Contact with Open Air

Since outside air never enters the pump, it is suitable for:

- Vacuum operations

- Handling fluids sensitive to air exposure

- Pharmaceutical and chemical processes where contamination is a risk

Wide Pressure and Temperature Compatibility

The absence of a shaft seal allows these pumps to handle:

- High-pressure liquids

- High-temperature or low-temperature fluids

- Materials with high melting points

This makes them extremely versatile across industries.

No Lubrication Required

With no lubrication oil needed, the pumps offer:

- Zero contamination risk

- Reduced maintenance effort

- Simplified operation

Compact and Space-Saving

The motor shaft doubles as the pump shaft, resulting in:

- A compact, lightweight design

- Minimal installation space requirement

- Easy access for overhauls and maintenance

Quiet Operation

Without a motor cooling fan, noise levels are greatly reduced, improving safety and comfort in industrial environments.

Energy Efficiency

The pump’s design optimises motor and impeller efficiency, minimising power consumption without compromising performance.

Industrial Applications

Hydrodyne Teikoku multistage pumps are widely used across sectors where reliability and high pressure are essential:

Power Generation

- Boiler feedwater systems deliver water at high pressure

- Steam condensate return lines

- Cooling water circulation

Petrochemical & Oil & Gas

- Circulation of hydrocarbons and chemicals

- High-pressure transport in refineries

- Safe handling of flammable or hazardous liquids

Chemical Manufacturing

- Transfer of corrosive or high-temperature chemicals

- Process circulation in reactors and mixers

- Handling sensitive fluids that must remain uncontaminated

Water Treatment & Desalination

- High-pressure water transfer for reverse osmosis systems

- Long-distance pipelines in industrial and municipal systems

- High-pressure pumping in filtration processes

Industrial Cooling Systems

- Circulation of coolants in large factories

- Maintenance of temperature control in high-precision processes

Advantages of Hydrodyne Teikoku Multistage Pumps

- Reliable high-pressure delivery

- Energy-efficient operation

- Durable construction for long-term performance

- Low maintenance requirements

- Compact and flexible design

- Leak-free operation for safety and environmental protection

- Quiet operation for better workplace conditions

Conclusion

Our multistage pumps are a dependable choice for industries requiring high head, low flow, and high-pressure fluid transfer. Their leak-free design, quiet operation, wide temperature and pressure compatibility, and energy efficiency make them suitable for a wide variety of applications—from boiler feed and chemical circulation to water treatment and industrial cooling.

For industrial operations looking for safe, reliable, and efficient high-pressure pumping solutions, Hydrodyne Teikoku’s multistage pumps offer performance and peace of mind, tailored to meet the most demanding requirements.

Frequently Asked Questions (FAQs)

1. What are multistage pumps used for?

They are ideal for high-pressure applications like boiler feed, chemical circulation, and long-distance fluid transfer.

2. How do they create high pressure?

Liquid passes through multiple impellers in series, each stage adding incremental pressure.

3. Can they handle corrosive or high-temperature fluids?

Yes. Hydrodyne Teikoku uses materials and seals suitable for aggressive, hot, or sensitive liquids.

4. Are they energy-efficient?

Yes. Stepwise pressure increase reduces energy consumption compared to single-stage pumps.

5. Can they act as booster pumps?

Yes, they can boost pressure in pipelines or systems where extra pressure is needed.

6. Which industries benefit most?

Power generation, chemical manufacturing, petrochemicals, water treatment, industrial cooling, and other high-pressure applications.

7. How reliable are Hydrodyne Teikoku multistage pumps?

With hermetic sealing and precision components, these pumps provide consistent performance with minimal maintenance.