Hydrodyne Teikoku Multistage Pumps: High-Pressure Centrifugal Solutions

September 25, 2025

How KOH Application Pumps Improve Process Efficiency in Manufacturing

October 24, 2025In industrial refrigeration, reliability and precision are non-negotiable. From chemical plants to cold storage facilities, food processing units, and large-scale HVAC systems, the efficiency of the refrigeration system hinges on how effectively the refrigerant is circulated. Even minor interruptions in this circulation can cause operational downtime, energy waste, or even safety hazards.

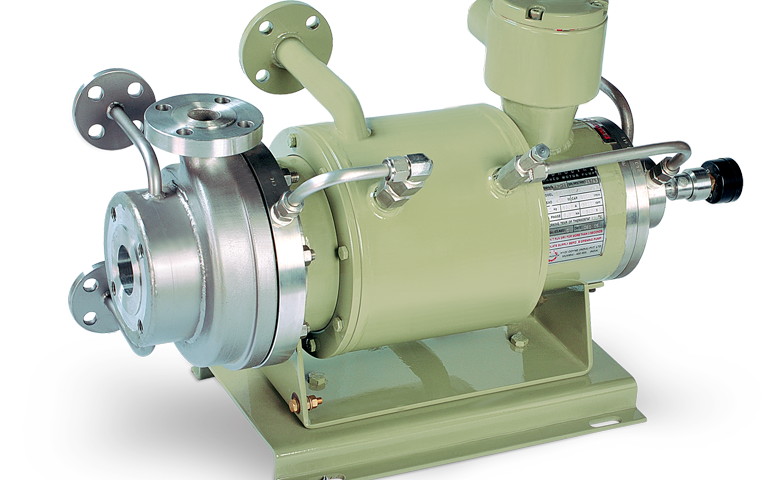

At Hydrodyne Teikoku, we understand the critical role that refrigerant circulation plays. Our LPA liquid refrigerant pump has been engineered to deliver safe, efficient, and reliable performance across a wide range of industrial applications. With decades of experience, we’ve focused on producing pumps that are leak-free, low-maintenance, and capable of withstanding the rigours of demanding environments.

In this article, we’ll walk through 15 key facts about the LPA liquid refrigerant pump, expanding on each to show why it’s trusted in industries where performance and safety cannot be compromised.

1. Purpose-Built Design

The LPA liquid refrigerant pump is designed specifically for refrigerant circulation in industrial refrigeration systems. Unlike general-purpose pumps, it takes into account the unique properties of refrigerants, such as low boiling points, high vapour pressures, and sensitivity to contamination.

We have engineered the pump to ensure smooth, consistent flow and reliable operation, making it suitable for systems that demand exacting temperature control, whether in food processing, pharmaceuticals, or chemical industries.

2. Hermetically Sealed

Safety and leak prevention are central to our pump design. The LPA liquid refrigerant pump features a hermetic seal, which ensures that the refrigerant cannot escape into the environment.

This design is particularly important for handling:

- Flammable or hazardous refrigerants

- High-value or difficult-to-replace fluids

- Environments with strict safety or environmental regulations

By eliminating the risk of leakage, we ensure that our pumps contribute to operational safety while reducing environmental impact.

3. Compact Footprint

Industrial plants often have limited space, making compact equipment a practical necessity. The LPA liquid refrigerant pump integrates the motor and pump into a single unit, reducing installation space requirements and simplifying system layout.

This compact design also facilitates easier maintenance and upgrades, allowing engineers to access the pump quickly without disrupting other equipment or requiring major modifications to existing infrastructure.

4. Corrosion-Resistant Materials

Refrigerants, especially in chemical or industrial applications, can be corrosive. That’s why we use high-quality, corrosion-resistant materials in the construction of the LPA liquid refrigerant pump.

From impellers to pump casings, every component is selected to withstand chemical exposure, ensuring longevity and reliable performance over the pump’s operational life. This durability is particularly valued in industrial environments where downtime can be costly.

5. Low Noise Operation

Noise can be more than a minor inconvenience; in industrial settings, it can affect workplace safety, comfort, and even compliance with local regulations. The LPA liquid refrigerant pump has been designed to operate quietly, minimising vibrations and mechanical noise.

By reducing operational noise, we help create a safer, more comfortable working environment, particularly in facilities where operators spend long hours monitoring and managing machinery.

6. Energy-Efficient

Energy consumption is a critical factor in industrial operations. Our LPA liquid refrigerant pump integrates the motor and pump in a way that maximises efficiency, reducing power consumption without sacrificing performance.

For facilities with continuous refrigeration requirements, this efficiency translates into significant cost savings and a reduced carbon footprint. It’s part of our commitment to sustainability while ensuring industrial reliability.

7. Wide Temperature Range

Refrigeration systems often require pumps that can operate across a broad temperature spectrum. The LPA liquid refrigerant pump is designed to handle low-temperature fluids typical of industrial refrigerants, as well as moderate-temperature applications where stability and consistency are key.

This flexibility ensures that the same pump model can serve multiple operational needs, reducing the need for multiple specialised units and simplifying inventory management for plant engineers.

8. Consistent Flow Rate

Stable refrigerant flow is essential for maintaining precise temperature control in industrial systems. The LPA liquid refrigerant pump ensures a consistent flow rate, supporting smooth and reliable cooling across all sections of a system.

Whether in cold storage warehouses, food processing plants, or chemical reactors, this consistency helps prevent temperature fluctuations that could affect product quality, energy efficiency, or safety.

9. Durable Performance

Industrial refrigeration demands equipment that can withstand continuous operation. Our LPA liquid refrigerant pump is built for durability, with precision-engineered components that ensure long-term performance.

We understand that downtime can be expensive and disruptive, so our pumps are designed to operate reliably over extended periods, even under challenging conditions.

10. Minimal Maintenance

Maintenance is often one of the largest operational costs for industrial facilities. The LPA liquid refrigerant pump has fewer moving parts and a hermetically sealed design, which reduces the likelihood of component wear and fluid contamination.

This means less frequent servicing, fewer spare parts, and more predictable operational schedules, all of which contribute to lower total cost of ownership.

11. Safe for Sensitive Applications

Some fluids are sensitive to contamination or exposure to air. The hermetic sealing and careful material selection in the LPA liquid refrigerant pump make it suitable for these sensitive applications, including:

- Pharmaceuticals

- Specialty chemicals

- High-purity industrial processes

By preventing leaks and contamination, the pump protects both the process and the people handling it.

12. Versatile Installation

The LPA liquid refrigerant pump can be easily integrated into new refrigeration systems or retrofitted into existing setups. Its compact and modular design ensures that installation is straightforward, minimising downtime during upgrades or system expansions.

This versatility allows plants to adapt to changing operational requirements without extensive modifications to their infrastructure.

13. High Reliability

Reliability is at the core of our design philosophy. The LPA liquid refrigerant pump is engineered to perform consistently under continuous operation. Its robust construction, coupled with precision engineering, ensures that it can withstand the demands of industrial environments without compromising performance.

Operators can rely on the pump to maintain consistent refrigerant circulation, reducing the risk of system failure or interruptions.

14. Supports Regulatory Compliance

Many industrial facilities are subject to stringent environmental and safety regulations. By being fully hermetically sealed, constructed from corrosion-resistant materials, and designed for safe refrigerant handling, the LPA liquid refrigerant pump supports compliance with regulatory standards.

This compliance reduces the risk of fines, environmental incidents, and operational shutdowns, while also reinforcing the facility’s commitment to safety and sustainability.

15. Wide Industrial Applications

Finally, the LPA liquid refrigerant pump is versatile across multiple industries:

- Food Processing & Cold Storage: Maintains stable temperatures for preservation and quality control.

- Chemical & Pharmaceutical: Ensures safe and precise cooling of sensitive reactions and formulations.

- Industrial HVAC Systems: Supports large-scale air conditioning and refrigeration systems efficiently.

- Marine & Offshore: Circulates refrigerants reliably in confined or challenging environments.

- Petrochemical & Refinery Plants: Maintains continuous refrigerant circulation for safe operation.

These applications highlight the pump’s adaptability and value across diverse industrial settings.

Why We Choose Hydrodyne Teikoku LPA Liquid Refrigerant Pumps

At Hydrodyne Teikoku, we design our LPA pumps with one goal in mind: to provide safe, reliable, and efficient refrigerant circulation. By combining hermetic sealing, durable materials, compact design, energy efficiency, and quiet operation, we create a solution that addresses the unique challenges of industrial refrigeration.

From installation to operation and maintenance, the LPA liquid refrigerant pump simplifies processes while ensuring that plants operate safely, efficiently, and with minimal disruption.

Conclusion

The LPA liquid refrigerant pump represents the culmination of decades of engineering expertise. With features like leak-free operation, consistent flow rates, wide temperature handling, energy efficiency, and low maintenance, it is a dependable choice for industrial refrigeration systems across sectors.

For facilities seeking a pump that combines safety, efficiency, and reliability, the LPA Liquid Refrigerant Pump from Hydrodyne Teikoku provides a solution designed to meet modern industrial demands. By integrating this pump into your operations, you benefit from both performance and peace of mind, knowing that critical processes are supported by robust and trusted technology.