Choosing the Right Canned Motor Pump for Your Application

August 24, 2024

Innovations In Canned Motor Pump Technology: What’s New For Indian Markets?

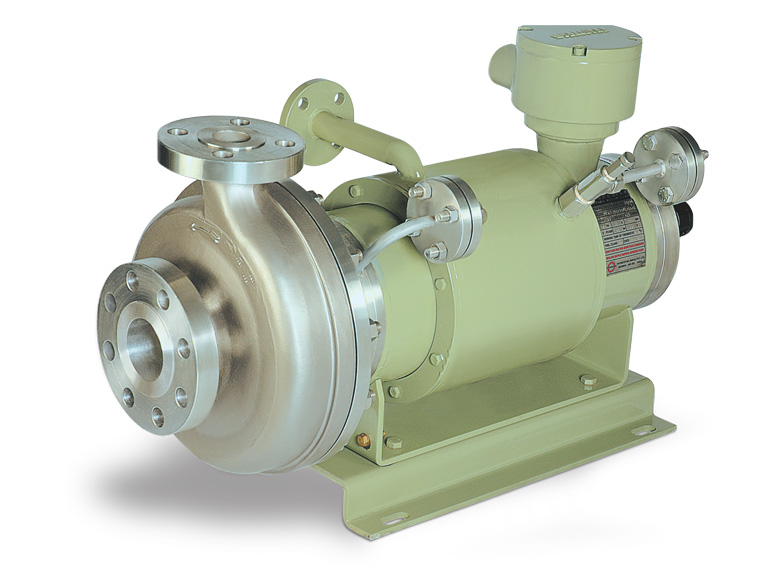

August 29, 2024When choosing Canned Motor Pump Manufacturers In India, certain aspects need to be given prime attention in order to identify the best motor pumps. Over time and with technological advancement, industries have become more complex, thus the need to select the right pump to handle the task. Hydrodyne Tiekoku India Pvt. Ltd., an Indian organisation and a reputed name in the global market, has been supplying various industrial canned motor pumps and high-quality canned motor pumps for different requirements.

1. Seal-Less Design for Leak Prevention

The remarkable aspect of canned motor pumps is that they do not have seals to cause leakage as other types of pumps do. This is especially relevant in industries where the handling of fluids that are considered hazardous or that corrode is routine. A canned motor pump from the best Indian manufacturers will be one whose motor is enclosed and is separate from the liquid being pumped. This design also has the added advantage of eliminating the build-up of leaks while at the same time minimizing the regularity of maintenance, hence cutting down the pump cost.

2. Energy Efficiency

One area where a lot of attention is paid is energy in any production process of an industrial nature. Today, new model canned motor pumps that leading Indian manufacturers manufacture can be categorized as energy efficient. Such pumps are usually embodied with motors that have been designed in a way that they do not waste so much energy when in operation, and they utilize new materials that help minimize energy loss. Selecting an efficient pump from the onset will mean that you have an opportunity to reduce your operation costs and, at the same time, reduce your negative impact on the environment.

3. Durability and Material Quality

Some of the factors that have an impact, especially on the durability of the canned motor pump, include the type and quality of the material used. Pumps constructed from corrosion-resistant alloys and superior strength materials are more likely to survive aggressive industrial conditions and have more extended productivity. Hydrodyne Teikoku India Pvt. Ltd of India, for instance, tries to use the best material that will enable the manufacturer to cope with the most severe applications.

4. Advanced Cooling Systems

Cooling is another crucial aspect that needs to be well done in order to get the best out of the canned motor pump. This may result in excess heat, which is bad for the pump because it shortens its reliability and durability. Some of the essential options that should be considered include the heat exchange type and the fluid flow rate enhancement. These systems help maintain the efficiency of the motor operation at high temperatures with heavy loads, in turn increasing the reliability of the pump and increasing its life span.

5. Ease of Maintenance

In motor pump systems, canned pumps are preferred because of the low maintenance requirements, but when there is a need to access the pump, then accessibility is essential. Manufacturers of pumps operating in the Indian market that adhere to the importance of designs that can be easily used will provide pumps that can easily be disassembled and serviced sparingly or without the assistance of professional tools. This not only decreases the time taken to maintain but also reduces maintenance costs.

6. Compliance with Industry Standards

Conformity to the industry set policies is significant, especially in areas that embrace issues of safety and ecology. Some of the major Canned Motor Pump Manufacturers In India include Hydrodyne Teikoku India Pvt. Ltd, which assures their products conform to the recognized standards of the country and in the international market, usually indicated in the form of ISO certification. This compliance ensures that the pump will run effectively as well as safely in your activities.

7. Customization Options

All industries are different, so their requirements are different, and a standard industrial solution may only sometimes be the most optimal. Currently, there are pump manufacturers based in India, such as Hydrodyne Teikoku India Pvt Ltd, where one can choose the pump’s model based on the customization he or she requires. There often needs to have a specific flow rate, specific pressure capabilities or unique compatibility with particular fluids, and all can be achieved through customization to ensure that the pump you choose for your system will be compatible with the system and can perform at its best.

Conclusion

When choosing a Canned Motor Pump Manufacturer In India, one has to focus on specific parameters such as seal-less construction, efficiency, rigid mechanical construction, effective cooling system or module, accessible maintenance features, adherence to standards, and options for customisation. Regarding these factors, you can specify that the pump you choose will meet operational requirements and provide excellent value in the long term. Among the leading manufacturers of canned motor pumps are Hydrodyne Teikoku India Pvt. Ltd offers quality canned motor pumps that encompass all these features, making it the preferred brand among most industries in India.