Why Hermetic Canned Motor Pumps Are Preferred for Hazardous Media

December 30, 2025

What Is a Hermetically Sealed Canned Motor Pump?

February 2, 2026In the rapidly evolving landscape of industrial fluid handling, canned motor pumps have emerged as one of the most critical technologies driving safety, efficiency, and sustainability across high-stakes sectors. As we step into 2026, the technology behind these pumps continues to mature in response to market demand, environmental regulations, digital transformation, and energy efficiency targets. At HydrodynePump Teikoku, where we have been manufacturing state-of-the-art canned motor pumps for over two decades, these advancements are not just trends; they define the future of leak-free pumping solutions.

Understanding the Canned Motor Pump Advantage

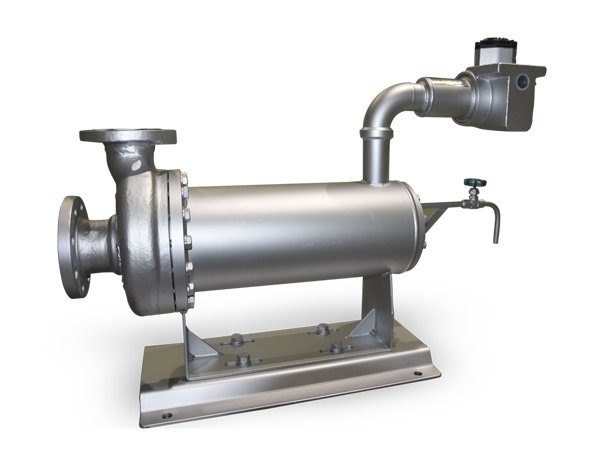

Before diving into the latest innovations, it’s important to revisit what makes canned motor pumps indispensable in industrial applications. Unlike conventional pumps, a canned motor integrates the motor and pump into a hermetically sealed, single housing. This design eliminates the need for external mechanical seals, reducing leak risk and maintenance requirements while improving reliability especially for hazardous, toxic, or high-pressure fluids.

This inherent safety and reliability have made canned motor pumps the preferred choice across chemical processing, pharmaceuticals, nuclear facilities, oil and gas, and other demanding industries where risk, downtime, and environmental impact carry high costs.

Trend 1: Smart & Connected Pump Technology

In 2026, one of the defining shifts in canned motor pumps is the integration of digital intelligence and connectivity. Industry 4.0 and IIoT (Industrial Internet of Things) are reshaping how industrial assets operate, and canned motor pumps are no exception.

Manufacturers today are embedding sensors and remote monitoring systems that continuously collect operational data such as vibration, temperature, flow, and motor performance. This data can be streamed in real time to central analytics platforms for predictive maintenance, reducing unexpected breakdowns and extending equipment life. By transitioning from reactive to proactive maintenance, plants can lower both downtime and lifecycle costs.

For HydrodynePump Teikoku’s customers, this means pumps that not only operate efficiently but also communicate performance insights directly to operators, enabling smarter decisions in critical process environments.

Trend 2: Energy Efficiency & Sustainability Focus

Sustainability isn’t a buzzword, it’s a business reality. Global industrial sectors are under pressure to reduce energy consumption and comply with stringent environmental standards. Energy-efficient canned motor pumps contribute directly to these goals due to their integrated motor design, optimized hydraulics, and reduced friction losses.

The market for energy-saving canned motor solutions continues to grow as companies seek to lower both carbon footprint and OPEX (operating expenses). By leveraging advanced motor technologies and hydraulic design improvements, modern canned motor pumps now deliver higher efficiency with lower input power, directly supporting sustainability targets without compromising performance.

HydrodynePump Teikoku’s engineered solutions support these goals delivering robust energy performance even in extreme operating conditions.

Trend 3: Advanced Materials & Harsh Environment Engineering

Industrial environments today demand far more from pumping systems than they did just a decade ago. With diversifying fluid chemistries and more extreme operating environments, canned motor pump manufacturers are investing in advanced materials science.

Innovative alloys, corrosion-resistant coatings, high-temperature alloys, and enhanced sealing media are enabling pumps that can handle aggressive, abrasive, or high-temperature media reliably. These materials extend service life, reduce unplanned maintenance, and enhance safety particularly in sectors like petrochemicals, process chemicals, and power generation.

For B2B purchasers who operate under tight production windows, this translates into operational continuity and reduced lifecycle cost.

Trend 4: Customization & Application-Specific Solutions

No two industrial applications are exactly the same. Recognizing this, the canned motor pump industry is moving away from generic “one-size-fits-all” designs toward application-specific customization.

Manufacturers today tailor pump characteristics such as impeller geometry, material selection, motor configuration, and system integration to specific client requirements. This allows for optimized performance whether the pump is handling cryogenic refrigerants, corrosive chemical slurries, or high-pressure thermal fluids.

This trend aligns perfectly with HydrodynePump Teikoku’s approach: engineering solutions that address the unique challenges of our clients rather than forcing a standardized product fit.

Trend 5: Expanded Market & Application Footprint

The global canned motor pumps market continues to expand, with increasing adoption in sectors like water treatment, HVAC, renewable energy, and even challenging applications like submersible and multiphase fluid environments. Market projections suggest substantial growth in market size and demand as industries emphasize leak-free, low-maintenance fluid handling.

This expanded footprint underscores the versatility and reliability of canned motor technology and positions manufacturers like HydrodynePump Teikoku at the center of tomorrow’s industrial fluid systems.

Conclusion: The Road Ahead For 2026 and Beyond

As we advance through 2026, the canned motor pump landscape is being reshaped by digitalization, sustainability imperatives, advanced material technologies, and a rising demand for precision solutions tailored to industry needs.

For B2B stakeholders, these innovations are not just performance enhancements, they are business enablers that reduce risk, improve operational efficiency, and support long-term sustainability goals.

At HydrodynePump Teikoku, our legacy of manufacturing high-quality canned motor pumps positions us at the forefront of these trends. We remain committed to innovation, deep application expertise, and delivering fluid handling solutions that empower our customers to thrive in increasingly complex industrial environments.

Let’s engineer the future of pumping technology together.