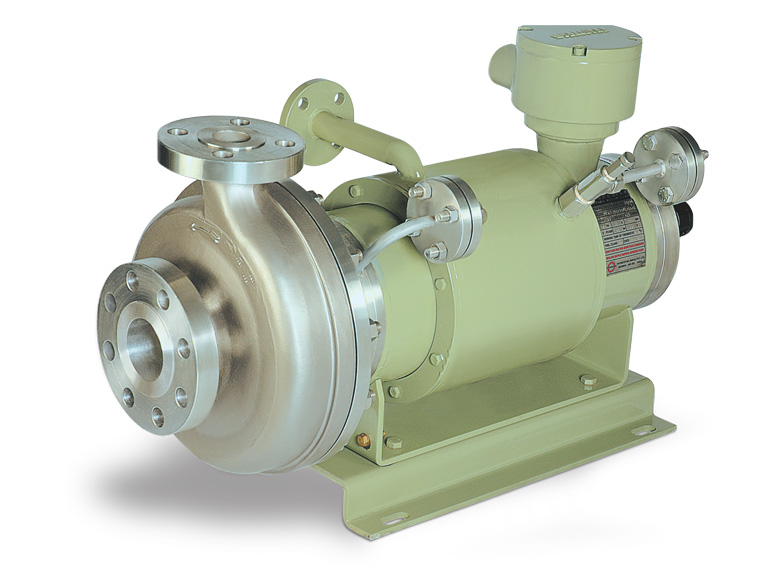

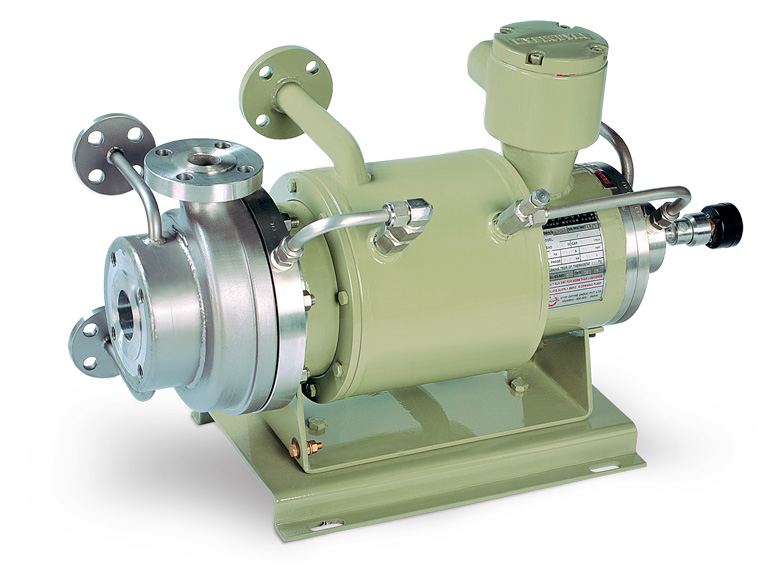

Diving into the World of Canned Motor Pumps: Keeping It Simple and Smart

December 29, 2023

The Quiet Transformers: A Deep Dive into the Evolution of Canned Motor Pump Tech

December 29, 2023Let’s explore the realm of Canned Motor Pumps (CMPs) and solve the riddles of safety requirements and regulatory compliance. Just the essentials of why these rules are important and how they affect our day-to-day work with CMPs

Table of Content

Regulatory compliance & and safety standards for CMP (Canned Motor Pumps)

- What’s Compliance

- Safety Standards

- Quality Assurance

- Green Machines

- Safety First

- Preventing Accidents

- Employee Well-being

- Long-Term Savings

Cutting Through the Red Tape

Why should we bother with regulatory compliance and safety standards for CMP? Well, – you wouldn’t hit the road without following traffic rules, These guidelines are our traffic rules for pumps. They’re there to keep things smooth, prevent mishaps, and ensure everyone’s safe and sound.

What’s Compliance

Now, let’s break down the big term – regulatory compliance. It’s like following a rulebook but for pumps. Different regions have different sets of rules for industrial gear, and CMPs are no exception. It’s not just about ticking boxes; it’s about making sure the pumps hitting the market are top-notch – reliable, safe, and up to the mark.

Safety Standards

These are like the unacknowledged icons in our pump story. They set the bar for how a pump should be designed, built, and operated. It’s not just about protecting the pump itself; it’s about keeping everyone around it out of harm’s way. We’re talking about a blueprint for pump safety here.

Quality Assurance

Think of regulatory compliance and safety standards as your quality control friends. They’re there to make sure CMP manufacturers are delivering the good stuff. We’re not just talking about fancy features – we’re talking about pumps that won’t let you down when you need them the most. It’s about ensuring quality and reliability, plain and simple.

Green Machines

We’re all about being eco-friendly, Well, regulatory compliance often includes measures to make sure CMPs are playing nice with Mother Nature. No one wants a pump causing trouble for the environment. These rules make sure our pumps are on the green team, not the naughty list.

Safety First

Safety standards are like the guardians of your CMP. They’re there to make sure the pump is designed to be as safe as possible during operation. From the materials used to the way it’s put together, safety standards cover it all. It’s not just about protecting the pump; it’s about keeping your workplace safe.

Preventing Accidents

Accidents are no one’s idea of a good time, especially when big machines are involved. Safety standards are the icons working behind the scenes to prevent accidents. Whether it’s dodging leaks, ensuring electrical safety, or keeping things from overheating, safety standards are the superheroes keeping your CMP in check.

Employee Well-being

Now, let’s talk about the people working elbow-deep with CMPs every day. Safety standards make sure employees aren’t at unnecessary risk. From installation to maintenance, these guidelines ensure the human element is considered.

Long-Term Savings

Believe it or not, following regulatory compliance and safety standards isn’t just about playing by the rules. It’s a smart move financially. Yeah, it might feel like an upfront investment, but down the road, it pays off. CMPs that meet these standards are more likely to be durable, reliable, and need less maintenance – that’s cash staying in your pocket.

So, there you have it – the lowdown on why regulatory compliance and safety standards matters for Canned Motor Pumps. It’s not just bureaucracy; it’s about having pumps that are safe, reliable, and easy on the environment.