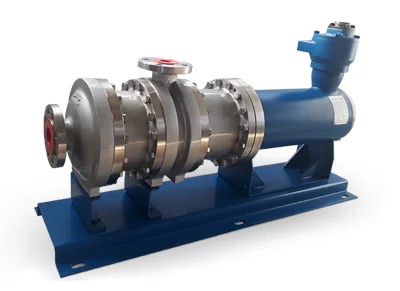

Tips To Choose The Right Canned Motor Pump

June 5, 2024

Reasons To Use Canned Motor Pumps In Chemical Industry

June 13, 2024Canned Motor Pumps (CMPs) come up with innumerable benefits to the heavy-duty industries. Leakage prevention, high reliability, rigorous materials, low maintenance costs, durability, environmental protection, etc; all these benefits are assured through Canned Motor Pumps.

These pumps are the modern solution to the older problems caused in an industry such as leakage, regular maintenance, and poor materials. In this article, we’ll have a look at the industries where canned motor pumps perform a remarkable job and have made themselves the best to handle any kind of fluids safely. Let’s have a deeper knowledge about the top 5 applications for Canned motor pumps.

-

Nuclear Sector:

This is one of the critical sectors where Canned Motor Pumps CMPs are extensively used. This sector requires proper handling of hazardous, radioactive liquids that are used on a regular basis. The nuclear power plants of various companies use this CMP to ensure the safety of their operations. The industry undoubtedly deals with the toxic gases or fluids that can lead to harmful emissions to the surrounding environment, ultimately risking the lives of people. The assurance of zero emissions is only given by canned motor pumps.

-

Refineries and Petrochemicals:

Canned Motor Pumps safeguard these industries efficiently due to their robust materials. These industries include work such as crude oil transfer, distillation process, transferring corrosive and hazardous fluids, etc, which are easily managed through these canned motor pumps. The pumps are made of rigorous and corrosive materials that withstand toxic fluids. These fluids can be stored for an extended period of time. Refineries also have petrochemical units in it where oils and adhesives are integrated.

-

Heavy & Speciality Chemicals Sector:

The pumps are largely used in the heavy and speciality chemical sector. These industries deal with dangerous chemicals like acid and alkali. These chemicals require proper handling and it is effectively done with canned motor pumps’ leakage prevention quality. The sensitive materials that are used for the production of pharmaceutical-grade chemicals are maintained and sustained by these canned motor pumps. It is also useful in maintaining temperatures in the distillation columns and chemical reactors.

-

Pharmaceuticals & Food Industries:

The food and pharmaceutical industries require proper hygiene and aseptic management. The safety standards should always remain high while handling the fluids of this industry. Thus, the canned motor pump with API 685 standards is the best choice one can make to ensure contamination-free activities. Production of safe and conservative medicines is assured by canned motor pumps that provide industries with sterile filtration. Their design helps them keep perishable food items, such as dairy products, bread, fish, etc., safe from being contaminated.

-

Cold Storage:

Cold storage includes multiple activities that are performed efficiently by Refrigeration Canned Motor Pumps. The activities include refrigerant circulation, brine pumping, hot gas defrosting, etc, which are massively assisted by these API 685 standard pumps. Cold storage has the primary and core function of providing refrigeration systems to maintain the quality of the items present inside. The pumps circulate water and uphold the low temperatures, leading to improved handling of fluids. The leak-free operation and effective heat transfer techniques are also adopted by these pumps to ensure that there is no ice buildup.

Conclusion

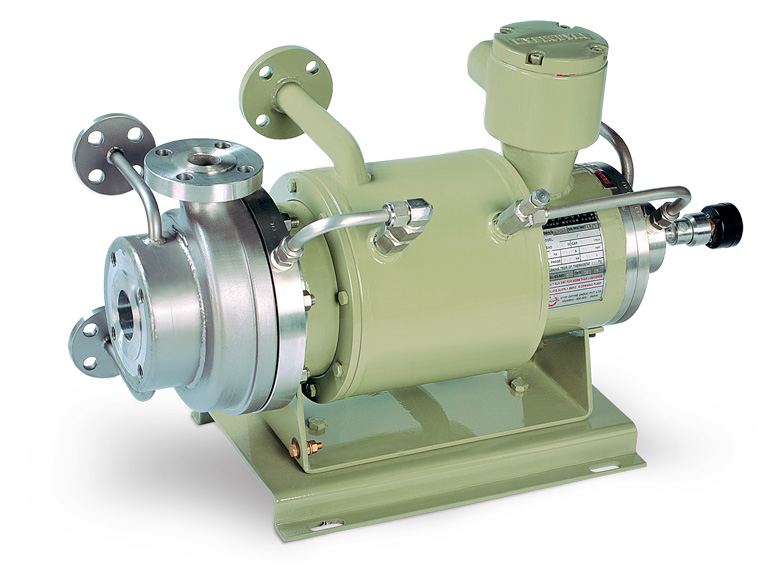

If you are still thinking about choosing the best-canned motor pumps that will quadruple your business operations, then you must check out Hydrodyne Pumps. They have a wide range of motor pumps to choose from, that’ll perfectly suit your requirements.. These pumps are API 685 standards to ensure complete safety and reliability.

Explore Hydrodyne Teikoku Pumps are today to maintain high standards of hygiene, reliability, and efficiency.