Ultimate Guide to Emission Free Pumps: Technology, Benefits, and Applications

August 20, 2024

Top Applications of Sealless Canned Pumps in Various Industries

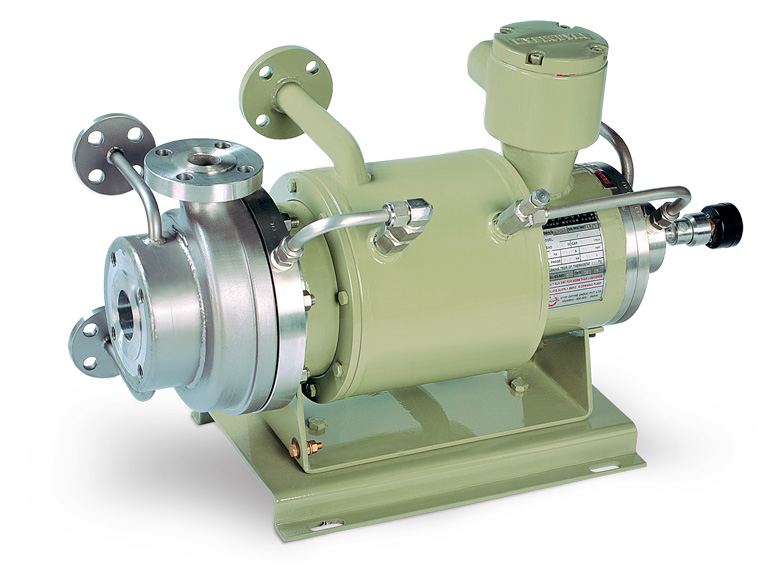

August 22, 2024Sealless canned Motor pumps are ideal solutions across versatile industries due to their leak-proof design and reliability. They never use mechanical seals, which generally become the weakest link in conventional pumping systems. Sealless canned pumps hermetically seal the environment to provide safe and efficient handling of hazardous, high-value fluids.

While looking towards a safe environment and roaming around various industries where Sealless Canned Motor Pumps are used, in India, the renowned name Hydrodyne Teikoku India Pvt. Ltd. has been serving its leakproof pumps for the past two decades. Their products have surpassed all the standard certifications, such as API-685, ISO-9000, and ANSI. The firm manufactures products and runs its business with the latest technology, and uses more than 20 years of experience to serve the best.

1. Chemical Processing Industry

The chemical processing industry often deals with aggressive, toxic, and corrosive substances. The design of sealless canned pumps makes optimal sense for this application since it eliminates the possibility of leakages with hazardous chemicals and provides a much safer work environment. They are meant to pump various chemicals like acid bases, solvents, etc. Not having seals removes the possibility of seal failure, reducing maintenance costs and downtime.

Sealless canned pumps are used in chemical manufacturing where the purity of the product is crucial. They are also resistant to high temperature and pressure, making them ideal in polymerisation or chlorination processes.

2. Oil and Gas Industry

The oil and gas industry requires operations to be performed under hazardous conditions for the most volatile, highly flammable fluids. The sector has extensively used sealless canned pumps, as they are durable and robust. These pumps also perform processes like crude oil transfer, gas sweetening, and offshore drilling.

Canned pumps are essential in this industry because they are explosion-proof, a crucial requirement for handling flammable liquids. They can also support fluids with high particulate counts and are suitable for upstream and downstream operations.

3. Pharmaceutical Industry

Sterile and contamination-free processes are of prime concern in the pharmaceutical industry. Such pumps are used with an array of pharmaceutical ingredients, from active pharmaceutical ingredients to solvents to finished products. Their hermetically sealed design ensures no contamination risk, making them ideal for cleanroom environments.

Such pumps are also valued for handling sensitive fluids that do not undermine their integrity. Whether used to produce vaccines, antibiotics, or other highly essential drugs, sealless canned pumps provide both reliability and accuracy in pharmaceutical production.

4. Power Generation Industry

In power plants, particularly nuclear and thermal types, Sealless Canned Motor Pumps are essential devices for the handling of severe media such as coolants, lubricants or radioactive substances. These pumps are vitally necessary to ensure that the cooling systems continue functioning safely and efficiently since even a small coolant leak in them can cause knock-on effects of catastrophic proportions.

This has been a juice for sealless canned pumps to keep the power generation industry operational by ensuring safe transfer of fluids at high temperatures and pressure and leakproof. These features mean they are also suitable for monitoring the 24/7 running of power plants robust enough to work in harsh conditions without much maintenance support.

5. Water Treatment Industry

One of the many applications where canned pumps can benefit is in water treatment facilities, especially wastewater and seawater desalination plants. The company’s pumps transport the vast array of chemicals used in the treatment process—from chlorine to sodium hypochlorite and other disinfectants. A tightly sealed design precludes the possibility of leaks, thereby safeguarding not only the environment but also plant personnel.

Sealless canned pumps are also ideal in desalination plants where the brine and other corrosives found in seawater present challenging conditions to a pump entraining its pumped product. Offering a high resistance to seawater and highly saline environments, these sensors can endure the most demanding applications yet deliver consistent results with little maintenance required.

6. Food and Beverage Industry

A necessity of the food and beverage industry is that they are compatible with pumping liquids without risk of contamination. Canned pumps without seals are usually between the beverage, dairy and other food processing industries. The twist cap and leakproof design keep the product pure even during use.

The pumps are well suited for such applications to avoid damaging product integrity, as is the case with syrups, undiluted sauces, and oils meant for ingestion. They are ideal for processes where clean room standards might be necessary.

Conclusion

Due to their immense success and the need in just about every industry for a product that could handle hazardous, corrosion or high-value fluids, Sealless Canned Motor Pumps are widely used. These pumps provide the best safety, efficiency and reliability for various chemical processing power generation applications. Sealless canned pumps make industrial processes safer and more productive by eliminating the risk of leakage and saving money on maintenance.