Safety Considerations When Operating Industrial Pumps And Motors

September 24, 2024

Understanding The Role Of Chemical Pumps In Safe Industrial Operations

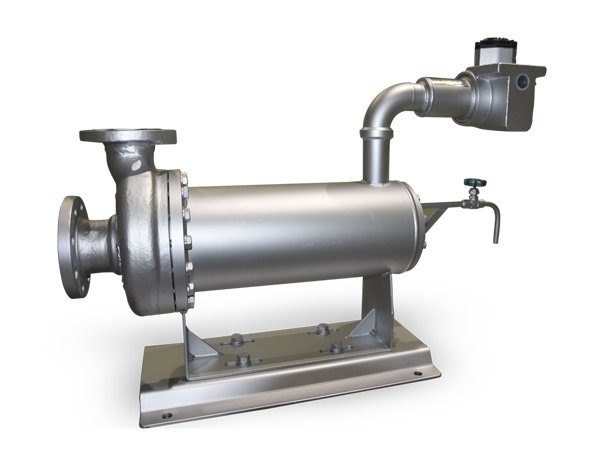

September 25, 2024Seal-less pumps have continued to become standard for many applications in industries due to benefits resulting in increased safety, efficiency, and reduced environmental impacts. These pumps are usually built to minimize the loss of fluids, as this may be a dangerous or expensive material. Since Hydrodyne Tiekoku India Pvt. Ltd. is a leading company specialising in offering the most innovative pumping systems, the company believes that Leak Free Pumps are critical in ensuring efficient industrial operations.

1. Enhanced Safety

It is highly critical to be safe within any industrial environment, mainly when working with corrosive, toxic, or flammable fluids. Sealless pumps are designed so that they do not allow for any form of fluid leakage, which can cause some hazards that may arise from the operation of pumps. This is more so in chemical plants, oil refineries, and the production of pharmaceuticals, whereby the safety of the personnel and the environment is paramount. Since these pumps do not have leakage concerns, industries enjoy a safer working environment as the risks of dangerous accidents are reduced.

2. Environmental Protection

Industrial leaks are societal disasters that pollute the soil, water, and air. leak free pumps are used to avoid such incidents and minimise risks that may be posed to the environment. Considering the industries that require lower emissions and even wastes, the operation of Leak Free Pumps assists companies in observing the laws and regulations that are set in place for the environment. This not only protects the environment but also is a way for a company to be a responsible member of society. As there is a shift in consumer’s perceptions of emissions and noise pollution, leak free pumps are crucial.

3. Cost Savings

Sealless pumps provide cost-effectiveness in that few fluids are lost, and there is a reduced need for Pump repairs and maintenance. Conventional leaky pumps are costly in terms of time lost resulting from downtimes, costs incurred in maintenance, and regular replacement of worn-out spare parts. Thus, the application of leak free pumps can help minimise such costs and increase the efficiency of business processes. Also, with no leaks, the precise amount of fluid needed to perform a particular task is utilised, and thus, this helps to keep costs down in organisations or industries.

4. Improved Reliability and Durability

leak free pumps that are designed for pumps have higher reliability and durability than standard pumps. These pumps are made using housing and internal components of high-strength materials and seal technologies that offer long-term efficiency even in challenging environments. This makes them ideal for use in industries that demand constant and predictable performance, such as petrochemicals, pharmaceuticals, and the food industry. This indicates that the life of the pumps is operational with minimal leakage occurrences, and therefore, less cycle time is affected, which translates to improved production and reduced operational hazards.

5. Compliance with Industry Standards

Sectors that require compliance with legislation involve chemical processing plants, pharmaceuticals, and oil and gas explorations, which deal with fluids. leak free pumps are specifically developed to conform to or surpass these requirements, therefore guaranteeing firms operate legally. This is especially the case in industries where compliance issues attract fines, legal proceedings, or harm to the organisation’s image. Therefore, when selecting pumps, companies should avoid those that leak as it will help them to get the best equipment that is safe and can work for a very long time.

6. Versatility and Flexibility

leak free pumps work for nearly any application, whether it is for transferring highly corrosive chemicals or processing pharmaceutical products gently. Due to their versatility in working with different types of fluids, they can be helpful in many industries. Also, these pumps come in different sizes and designs, which is typical of pumps, meaning one can order a particular type for an application. This versatility means that one can ensure that there are no leaks on the side of the pump while at the same time being able to ensure that the pumps can easily be incorporated into the existing systems, thus offering a versatile solution to many of the problems faced by the industrial sectors.

Conclusion

The advantages of Leak Free Pumps make them ideal for deployment in industrial settings as they provide safety, environmental conservation, cost-effectiveness, reliability, and industry compliance, besides being as versatile as possible. Pump manufacturers can reap tremendous benefits from the adoption of leak-free technologies in pump manufacturing and design, and this will go a long way in enhancing operational efficiency while minimising life hazards to the public. We at Hydrodyne Tiekoku India Pvt. Ltd. are in the manufacturing and supply of leak-free high-quality pumps to satisfy the demands of the modern industrial world with National and International standards of quality manufacturing so that your operations remain leakage-free.