E-BEARING MONITOR

E-Bearing monitor

Takes the “mystery” out of canned motor pump operation…continuously monitors the critical running clearance between the stator and rotor.

The exclusive E-bearing monitor is an electrical monitoring device available today that not only monitors the running clearance but indicates bearing condition. This allows the operator to plan for pump maintenance.

The exclusive E-bearing monitor makes Hydrodyne Teikoku the most reliable canned motor pump in the Industry today.

- Monitors and indicates rate of radial bearing wear

- Detects lost phase

- Shows reverse rotation

- The E-bearing monitor operates on the principle of induced voltage. A magnetic field is created in the EBM coils by the current flowing through the stator winding. In addition, a magnetic field is created by induced currents in the rotor.

- When the rotor is perfectly centered in the stator, the two magnetic fields are essentially concentric or balanced.

- When bearing wear occurs and the gap “B” between the rotor and stator decreases, a magnetic flux created by the imbalance in the magnetic fields causes an induced voltage in the EBM coils.

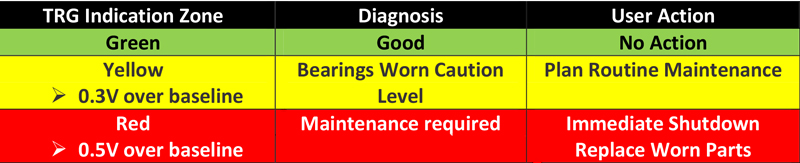

- This voltage is indicated on the EBM voltmeter. The meter is mounted on the pump terminal box as standard but is available as remote panel-mount.

EBM with phase sequence sensor in operation

EBM initial indication varies from pump to pump. Users can record the initial value to establish a baseline. This determines a point from which to monitor the wear arte of the bearings and establishes preventative maintenance schedules.