Expert Tips for Selecting the Best Canned Motor Pump Manufacturer for Industrial Applications

August 18, 2024

Top Applications for Sealless Canned Motor Pumps in Various Industries

August 20, 2024As organizations pay attention to the checklist of sustainable development, Emission Free Pumps have emerged as an essential factor in that agenda. These pumps have no blowing pollutants, which makes them suitable for use in many applications where there is an emphasis on safety to the environment and standards. Here, we will discuss how emission free pumps work, the advantages of using them, and the sectors in which they can be applied efficiently. In this regard, Hydrodyne Teikoku India Pvt. Ltd., a company in this line, has technologically superior emission free pumps that are distinguished as suitable for the outcomes of superior industries.

Understanding Emission Free Pump Technology

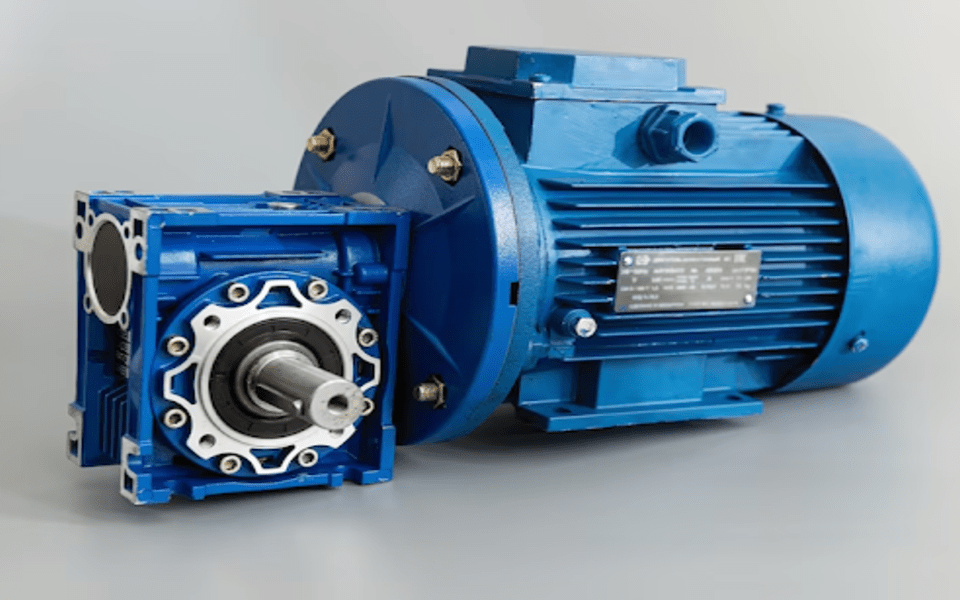

Seal-less pumps or emission free pumps are specifically designed to avoid the expulsion of dangerous gasses in the ambiance. The first type of these pumps relies on an airtight casing that completely surrounds the fluid that is being moved. It also does away with mechanical seals, which are usually the weak point of standard pumps and cause leakages. Conventional pumps, on the other hand, emit fluids from the suction and discharge faces owing to centrifugal force acting on the fluid. Still, emission free pumps employ some techniques such as magnetic drive or canned motor technique to transfer power to the impeller without exposing the system to the environment.

In a magnetic drive pump, the torque is transferred from the motor to the impeller with the help of magnetic coupling only. This helps eliminate the need for seals and sealants and wholly or significantly reduces any form of leakage of particular fluids. In the same way, canned motor pumps combine the motor and the pump, whereby the motor winding is enclosed in the pump case. This design not only helps in emission reduction but also guarantees the structural integrity and efficiency of this pump for handling aggressive and corrosive fluids.

Attributes Of Emission Free Pumps

- Environmental Protection: The most important advantage associated with emission-less pumps is the possibility of saving the environment from dangerous emissions. This is especially important in any industries that involve hazardous fluids, such as toxic, flammable, or corroding fluids; even a minor leakage could easily lead to catastrophe.

- Operational Safety: Clean pumps help reduce the level of exposure to chemicals at the workplace since they do not emit any hazardous chemicals. This is especially so in industries like chemical processing, the pharmaceutical industry, and the oil and gas industry, where the safety of the worker should always be a primary consideration.

- Low Maintenance Costs: The mechanical seals used in conventional pumps are often prone to leakage and require frequent servicing. There are emission free pumps that do not have seals; this means that they will not require frequent maintenance, which will add to the cost of working and time lost.

- Compliance with Regulations: Due to rising environmental concerns, various countries always tend to enforce regulatory practices; this makes emission-less pumps enable companies to meet the required standards. Due to its capability of expelling emissions, such types of pumps enhance operations that meet environmental standards.

- Energy Efficiency: With no emissions, it is often the case that emission free pumps are more energy efficient than sealed pumps. In these pumps, the technology is used to minimize the friction between the pump shaft and the casing, thus minimizing thermal losses to a great extent, which in turn means less energy is consumed.

- Extended Lifespan: Another that the company can benefit from is that with no seals in the emission free pumps, this implies that there are little parts that can degrade with time. This saves the pump’s lifespan and, therefore, makes it a cheaper option than regular pumps.

Applications Of Emission Free Pumps

- Chemical Processing: Some of the pumps used in the chemical processing industry include emission free pumps since the movement of corrosive and toxic chemicals requires extra precaution. Such pumps ensure that no poisonous products are expelled into the environment and that the well-being of the workers and the environment is enhanced.

- Pharmaceuticals: In the pharmaceutical industry, purity of fluids is vital. Pumps that do not emit can be helpful to transport delicate fluids without polluting them, thus making sure that the products are safe and of good quality.

- Oil and Gas: The oil and gas industry is involved with products that are highly flammable, toxic, and sensitive to their environment. This makes the emission free pumps essential, especially when handling these fluids, as they do not leak or explode.

- Food and Beverage: In the food and beverage industry, it is crucial to ensure that a high standard of hygiene and safety is maintained. Positive displacement pumps are employed to transport juice products, syrups, and dairy products because they do not contaminate the products.

- Water Treatment: Pumps used in water treatment plants employ emission control and deal with chemicals and other products that are used in water treatment. These pumps play a critical role in the water treatment system’s integrity because they facilitate the protection of chemicals from leakage and spilling.

- Nuclear Power: There are emission free pumps used in nuclear power plants where radioactive fluid is dealt with, thus requiring safe handling. These pumps do not have any seals to minimize or prevent leakage of radioactive material into the environment, hence improving people’s health.

Conclusion

Emission Free Pumps are a vital innovation for industries committed to sustainability and safety. With their advanced technology and numerous benefits, these pumps are indispensable in applications ranging from chemical processing to nuclear power. Hydrodyne Teikoku India Pvt. Ltd. offers cutting-edge emission free pumps that meet the demanding requirements of modern industries, ensuring both environmental protection and operational efficiency.