Understanding Flow, Pressure, and Capacity Requirements for API 685 Pumps

October 24, 2025

We are Sealless Canned Motor Pumps Manufacturer in Mumbai

October 27, 2025The importance of proven and dependable fluid handling systems within the industry has increased markedly over the past few decades. Applications ranging from power generation and chemical processing to desalination and boiler feed systems involve the transportation of fluids to high pressures. It is not easy to achieve and maintain these pressures within these industry systems; this is precisely where multistage pumps become absolutely important.

Multi-stage pumps are unique because of their capacity to significantly increase the pressures over what is generated from the single-stage pumps. In addition to this, they are able to maintain stable pressure over the long term, are energy efficient, and are not damaged within harsh operating conditions. It is important for engineers, plant managers, and systems designers to fully understand the operation, the range of applications, and the importance of these pumps for high pressure systems.

The focus of this article is to illuminate the fundamental principles behind multistage pumps, the merits of multistage pumps in addition to their strategic applications, and their role in initiating and maintenance within high pressure industrial systems.

Understanding Multistage Pumps

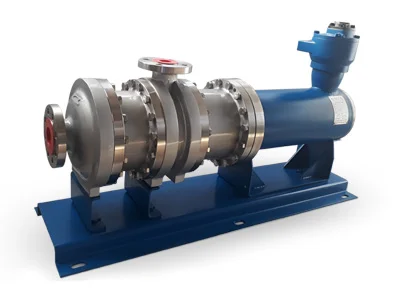

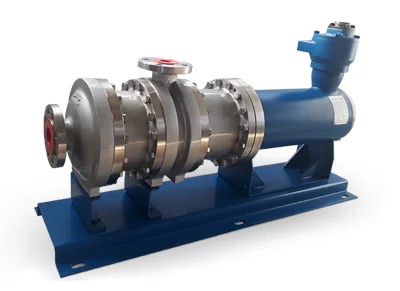

In order to understand the critical nature of multistage pumps for high pressure systems, it is crucial to have a grasp on their core structure. The most convenient way to think of a multistage pump is as a centrifugal pump with more than one impeller or “stage” mounted on a common shaft, each of which is enclosed in a single casing.

Each level generates additional energy to the fluid, which increases the pressure over time and the distance traveled in the pump. This controlled, gradual pressure increase maintains the flow and stability of the system.

A single-stage pump, on the other hand, incorporates only one impeller, which acts as a ceiling on the pressure produced. For applications requiring the transportation of fluids over long distances, or to significant possible heights, single-stage designs tend to underperform. The additional engineering in multistage designs, with impellers in series, works to counteract the deficiency.

How Multistage Pumps Work

The working principle of a multistage pump revolves around energy transfer through multiple impellers. The liquid enters the first stage, where it gains kinetic energy from the impeller. This energy is then converted into pressure as the fluid passes through the diffuser or volute. The process repeats through each successive stage, allowing the pump to build up pressure incrementally.

The overall discharge pressure of a multistage pump is the sum of the pressure developed by each stage, while the flow rate remains relatively constant. This makes them ideal for applications where high pressure but moderate flow is required.

A typical multistage pump configuration includes:

- Multiple impellers arranged in series to progressively increase pressure.

- Diffusers or volutes between stages to convert velocity into pressure.

- Shaft seals and bearings designed to handle axial thrust and maintain alignment.

- Casing options (horizontal or vertical) depending on space and system requirements.

This staged energy conversion process ensures smooth, vibration-free operation and efficient handling of fluids, even under extreme pressure conditions.

Why High-Pressure Applications Require Multistage Pumps

Multistage pumps are critical for instances requiring high pressures across various industries, such as feeding steam boilers, pumping feedwater in desalination plants, and transporting hydrocarbons in refineries. Every use case needs reliability, continuous operation, and precise pressure control.

Multistage pumps are able to cater to all of these requirements as they are able to achieve high discharge pressures without the need of large impellers and motors.

Effective Pressure Generation

The various system requirements for fluid to be pumped over large distances, uphill, or into pressurised systems is met as multistage pumps are able to achieve high pressures. This is due to the efficiency that they maintain while adding high incremental pressures.

In the case of boiler feed applications, multistage pumps are able to provide consistent flow into the system while maintaining boiler pressure which single stage pumps tend to struggle doing.

High Output in Compact Design

Higher pressure is obtained by multistage pumps without significant increase in pump size or motor power. Rather than employing one large impeller which is mechanically inefficient, multiple smaller impellers share the load. This makes for a compact and lightweight construction capable of outstanding mechanical performance without compromising balance or stability.

In addition to other advantages, multistage designs are space efficient and can be used in installations with limited floor space such as power stations, compact industrial plants or even offshore platforms.

Stable and Smooth Operation

Unlike single stage pumps which have a surge in pressure, pressure in multistage pumps increases gradually, offering smoother operation with less vibration. This gradual pressure build up minimises mechanical stress on the components and piping systems, reducing maintenance and extending service life.

Equally important, improved reliability is a result of balanced axial thrust which causes less wear on bearings and seals.

Cost Savings and Energy Efficiency

Multistage pumps in high pressure applications are very economical and the reason is the low energy consumption. Unlike oversized single stage pumps which are less efficient, these pumps are more efficient due to the shared load.

They also feature precise adjustable variable-speed control of flow and pressure for process requirements. In turn, this saves energy, minimising wear and operational costs over time.

Some energy-saving benefits include:

- Reduced power input for the same discharge pressure.

- Maximised flow control through variable frequency drives.

- Less balance maintenance downtime.

In continuous operation industries, the energy savings directly correlate with savings.

Reliability Under Extreme Conditions

High-pressure systems often operate in extreme conditions such as high temperatures, corrosive fluids, and rapid pressure changes. Multistage pumps are able to sustain these conditions.

Long-lasting pumps made with stainless steel, duplex alloys, and high-grade seal incorporate advanced technologies, allowing for reliable operations in extreme environments. Their modular construction accounts for more operational efficiency, as it is easy to repair and maintain these systems.

Key Industrial Applications

Multistage pumps play a vital role in a wide range of high-pressure applications. Their ability to deliver high head and consistent performance makes them indispensable across industries such as:

- Power Generation:

Used in boiler feedwater systems, condensate extraction, and cooling water circulation where precise pressure and reliability are essential. - Oil and Gas:

Applied in refinery operations, high-pressure injection, and transfer of hydrocarbons in both upstream and downstream processes. - Desalination Plants:

Essential for reverse osmosis systems where seawater must be forced through membranes at high pressures. - Chemical Processing:

Used for transferring chemicals safely under pressure without compromising flow consistency or system stability. - Water Supply Systems:

Employed in municipal and industrial water distribution where high-pressure pumping is required to overcome elevation or distance challenges. - Mining and Metallurgy:

Used for dewatering, process water transport, and slurry handling in deep mines and high-pressure circuits. - Firefighting Systems:

Provide high-pressure water supply for fire suppression systems in industrial and commercial facilities.

Each of these applications benefits from the precision, durability, and adaptability that multistage pumps bring to high-pressure systems.

Design Variations: Horizontal vs Vertical Multistage Pumps

Multistage pumps are available in both horizontal and vertical configurations, each suited to specific operating environments.

- Horizontal Multistage Pumps:

These are ideal for applications requiring high flow at high head. They are easier to maintain and service since components are more accessible. However, they may require more floor space. - Vertical Multistage Pumps:

These are preferred where space is limited. Their vertical arrangement saves floor area and allows for easy alignment with vertical piping systems. They are widely used in high-pressure water supply, desalination, and HVAC systems.

Choosing between horizontal and vertical designs depends on the available space, system layout, and maintenance considerations.

Factors to Consider When Selecting a Multistage Pump

Selecting the right multistage pump for a high-pressure system involves evaluating several critical factors to ensure efficiency and reliability.

- Required Head and Flow:

Determine the total dynamic head and flow rate needed for the application.

- Fluid Characteristics:

Assess viscosity, temperature, and corrosiveness to select suitable materials and seals.

- System Configuration:

Consider piping layout, elevation, and pressure losses.

- Operating Environment:

Ensure the pump is compatible with ambient conditions and potential contaminants.

- Energy Efficiency Goals:

Look for models that support variable frequency drives for energy savings.

- Maintenance Accessibility:

Choose a design that allows for easy inspection and servicing to minimise downtime.

A thorough evaluation ensures optimal pump performance and longer service life.

Maintenance and Monitoring

While multistage pumps are known for their durability, consistent maintenance and monitoring are key to long-term reliability.

Routine checks should include:

- Monitoring vibration and noise levels.

- Inspecting bearings and seals for wear.

- Checking alignment and coupling condition.

- Ensuring lubrication systems are functioning properly.

- Reviewing pump performance data for deviations from expected flow or pressure.

Integrating modern monitoring technologies, such as smart sensors and predictive maintenance software, helps detect potential issues before they cause downtime.

Advantages of Multistage Pumps in High-Pressure Systems

Multistage pumps offer several key advantages that make them the ideal choice for high pressure applications:

- Generated high pressure has a compact design.

- Reduced energy consumption due to balanced multi-impeller operation.

- Remarkable reduction in vibration and noise levels.

- The noise and vibration levels are particularly high.

- Less mechanical stress for greater life expectancy.

- Multistage pumps are particularly robust.

In summation, multistage pumps deliver the utmost balance of power, efficiency, and strength to ease the initiation and maintenance of high pressure applications.

Conclusion

In industrial applications that are extremely high tension, there is no room for error. Multistage pumps have proven to be the best option for generating high efficiencies, high pressures smoothly, and meeting process conditions, functionality range.

Their modular design, energy efficiency, and durability makes them critical in power plants, chemical processors, and water treatment facilities.

At Hydrodyne Teikoku, we understand that the right Hydrodynepumps can change the course of operations. From the safety standpoint, accuracy of pressure delivery no matter how tough the surrounding conditions are, is remarkable. Understanding the system requirements, and selecting the pumps that achieve both performance and efficiency, is the achievable goal of every industry. Hydrodyne is reliable and affordable every single time.

Frequently Asked Questions (FAQs)

- What is a multistage pump and how does it work?

A multistage pump is a centrifugal pump that contains two or more impellers mounted on a common shaft. As the liquid passes through each impeller, its pressure increases incrementally. This design allows the pump to deliver high discharge pressures efficiently, making it ideal for applications such as boiler feed, desalination, and high-pressure water systems. - Why are multistage pumps preferred for high-pressure applications?

Multistage pumps are preferred because they can generate much higher pressures than single-stage pumps while maintaining stable flow and energy efficiency. The multi-impeller design distributes the workload evenly, reducing mechanical stress and extending the pump’s lifespan. - What are the main industries that use multistage pumps?

These pumps are widely used across industries that require reliable, high-pressure fluid handling, including:

- Power generation (boiler feed and condensate systems)

- Oil and gas (injection and transfer applications)

- Desalination plants (reverse osmosis systems)

- Water treatment and distribution

- Mining and metallurgy

- Firefighting systems

- Are multistage pumps energy efficient?

Yes. The staged design allows multistage pumps to achieve the required pressure with smaller, more efficient impellers, reducing power consumption. When combined with variable frequency drives (VFDs), they provide even greater control and energy savings by adjusting speed to match system demand. - What is the difference between horizontal and vertical multistage pumps?

Horizontal multistage pumps are designed for high flow and easy maintenance, often used in industrial plants with sufficient space. Vertical multistage pumps, on the other hand, are more compact and ideal for installations where floor space is limited. Both deliver high pressure, but the choice depends on layout and accessibility requirements. - How should multistage pumps be maintained for reliable performance?

Routine inspection and preventive maintenance are key. Operators should:

- Monitor vibration, temperature, and noise levels.

- Check for seal and bearing wear.

- Ensure proper alignment and lubrication.

- Keep an eye on flow and pressure readings for early signs of deviation.

Proper care minimises unplanned downtime and extends service life.

- Why choose Hydrodynepumps for multistage pumping applications?

At Hydrodyne Teikoku, we design and manufacture Hydrodynepumps that deliver exceptional reliability, efficiency, and performance under the toughest conditions. Our multistage pumps are built to meet precise pressure and flow requirements while ensuring safe, energy-efficient, and long-term operation for industrial clients across various sectors.