Choosing the Right Seal-Less Pump: A Guide for Different Needs

August 22, 2024

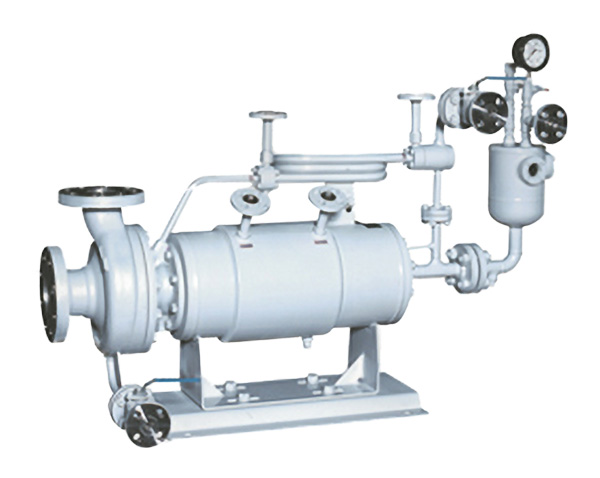

Choosing the Right Canned Motor Pump for Your Application

August 24, 2024Leak-free pumps are crucial for many applications in various industries as they provide numerous advantages that, in turn, increase their safety, efficiency or reliability. Unlike other pumps, which may easily leak due to weariness, damage, wrong sealing, or the like, leak-free pumps are developed so they do not leak at all throughout the process of pumping fluids. Leak-free pumps and their applications in numerous industries are described in this article to focus on their chief advantages.

Enhanced Safety and Environmental Protection

The first advantage of leak-free pumps is the increased safety of industrial zones. Originations in pumps may result in hazardous circumstances, especially when working with poisonous, flammable and corrosive substances. These leaks can be dangerous to the workers, the equipment, and the environment. Leak-free pumps save such risks as fluids spilling over, posing a danger to the personnel handling and transporting them as well as the environment in which the fluids are used.

However, Leak-Free Pumps show concern for environmental concerns. Seepage of such fluids further pollutes the ground, water availability, and air in the environment and is, in most cases, actionable in law. With the help of leak-free pumps, industries will minimize their effects on the environment, hence conforming to environmental standards.

Improved Efficiency and Reliability

When there is no leakage, the pumps cause the least wastage of the fluid and they are highly reliable. Conventional pumps may have energy losses occasioned by cracks that may affect their performance and result in high costs of operations. On the other hand, pumps that leak can have unstable pressure and flow rate meaning energy is not optimally used and the process runs disruptively.

Another advantage of the leak-free pumps is that they need little or no maintenance at all. As these pumps are made to avoid leakage, the use of seals and other parts is less, which results in less wear. This reduces the frequency of breakdowns, hence reducing maintenance costs and increasing pump life. There are many industries where equipment must be constantly running, so even minor reductions in downtime are of significant value; leak-free pumps facilitate this.

Cost-Effective Operation

It should be pointed out that better technology, which results in leak-free pumps, may entail higher first costs, but the overall costs are considerably lower. There is less leakage, fewer repairs and parts replacements, and fewer maintenance expenses. Also, leak-free pumps are energy efficient since less energy is used to operate them to the same level of effectiveness as leaky ones.

Leak-free pumps also benefit industries by eliminating the costs incurred in cleaning and managing fluid leakage. These savings, together with the avoidance of environmental fines and legal difficulties, make leak-free pumps cheaper when compared to other industrial uses.

Versatility in Applications

Leak-Free Pumps are beneficial and can be applied in almost any industry. They are especially useful in process industries where leakage cannot be tolerated, such as chemical processing, manufacture of drugs and medicine, food and drink production, and petroleum. Within these industries, the behaviour of the product under consideration regarding the ability to contain various fluids is a crucial factor towards the consistent quality of the final product, safety and compliance with multiple standards.

Furthermore, pumps can have various designs and be made of numerous materials, meaning that for any operating condition or type of fluid, a leak-free pump is available. It is this feature that can be regarded as a significant advantage as it enables industries to settle for a particular pump that is more appropriate for its use.

Also Read:- Is Your Leak-Free Pump Really Leak-Free? Essential Maintenance Tips

Conclusion

Leak-Free Pumps are characterised by various attributes such as safety, environmental considerations, efficiency, reliability, costs, and flexibility of use in industrial operations. By establishing a leak-free pump, industries will be in a position to have safe and efficient operations, hence cutting the expenses that may result from leakage and environmental pollution.

To industries in need of leak-free pumping, Hydrodyne Teikoku India Pvt. Ltd. is a submerged pump manufacturer and supplier of top-grade and certified leak-free pumps to suit your needs.