Key Benefits of Using Leak-Free Pumps in Industrial Applications

August 22, 2024

Key Features to Look for in Canned Motor Pumps from Indian Manufacturers

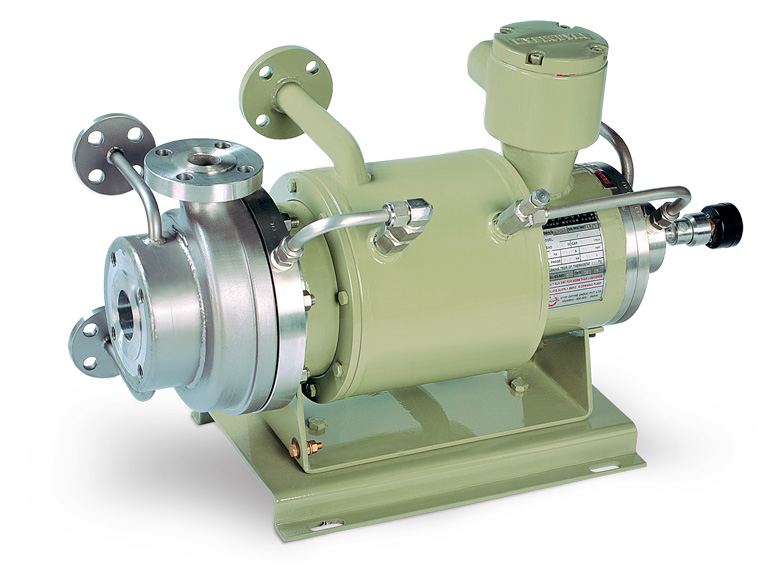

August 26, 2024The right choice of canned motor pump to use in the application is crucial to its success regarding efficiency, safety and durability. Canned Motor Pumps are distinct in design and are preferred, especially where a leak proof seal is essential when handling dangerous or aggressive fluids.

As the number of pump types is vast, knowing what matters most when selecting the right pump can significantly enhance a user’s experience. For those in need of canned motor pumps, Hydrodyne Teikoku India Pvt. Ltd., one of the premier manufacturers of the product, has provided tips on how to go about it.

1. Understand Your Fluid Characteristics

The first thing that one should do when selecting a canned motor pump is to consider some properties of the fluid that is to be pumped. They come in motor pump canned construction to deal with many fluids, such as corrosive, toxic and high-temperature fluids. However, this does not mean that all pumps available on the market are of the same quality. It depends on the viscosity of the fluid, the temperature and the chemical composition of the fluid. For example, if you are pumping highly corrosive fluids, the material that should be used in constructing your pump has to be anti-corrosive, like stainless steel or special alloys.

2. Consider the Operating Conditions

Operating conditions are one of the most crucial factors influencing the selection of a Canned Motor Pump. This includes the pressure and flow parameters in the system and the temperature and environmental conditions of the pump. The first criterion is to match the maximum operating pressure to get the required flow rate for the specific application.

3. Evaluate the Pump’s Efficiency

The energy consumed has to be utilised efficiently, which is an issue of great concern in specific industries. Canned motor pumps, as a class of pumps, are reputed to be highly efficient, bearing in mind factors such as their size and design, for they do not incorporate mechanical seals that contribute to overall frictional losses. When choosing the right type of pump, focus on the ones that will have efficient ratings for use. Usually, pumps are designed to cut energy consumption. Besides driving down operational costs, it also helps promote sustainable and environmentally friendly ways of doing business.

4. Check for Reliability and Durability

Durability and reliability are characteristics that should be considered, especially when the components are to be used in Industrial applications. From the list, there is a high probability that a buyer will find a reliable canned motor pump that is highly effective and will hardly ever require repairs. In particular, select pumps that have gained positive experience in similar uses. Another property to consider is the pump’s durability, especially when dealing with abrasive or high-temperature fluids.

5. Consider Maintenance Requirements

The other benefit that users can derive from the canned motor pumps is that they are easy to maintain. But that is not all there is to it; the maintenance of the selected pump also has to be easy. Choose the pumps whose access to the essential parts is easy, and no or little tools are needed to work on them. Also, focus on the question of spare parts accessibility and technical support from the manufacturer’s side.

6. Compliance with Industry Standards

Another important criterion used in choosing the canned motor pump is the Industry standards and certifications. It is also essential to maintain that the pump to be purchased conforms to standard regulatory bodies like the ISO, API or certain other standards according to the industry. Observing these standards helps in making sure that the pump meets the safety, performance and quality requirements applicable to your intended use. Teikoku pumps are industry standard and that gives the confidence when using the product that it has passed through all industry tests.

7. Customization Options

It is always a different story with every application; standard pumps may only fulfill some of your needs. In such cases, you need to consider the options available for customisation. Companies such as the Hydrodyne Teikoku India Pvt. Ltd came up with different solutions that may suit your business needs. Customisations such as special flow rate, pressure rating, or construction material guarantee that the pump to be used will be suitable for the intended job, hence improving overall efficiency and reliability.

Conclusion

The right canned motor pump can be selected based on fluid specificities, operation conditions, efficiency, reliability, maintainability and conformity and options for pantograph customisation. By considering these factors, you can guarantee that the pump you choose will fit your requirements and be worth the investment for a more extended period. Hydrodyne Teikoku India Pvt. Ltd. is one of the leading companies in the industry, majorly dealing in Canned Motor Pumps already developed to be ideal for use within a variety of industrial processes, hence the best option to incorporate into your pumping system.