API 685 Canned Motor Pumps: Leak-Free Pumping for the Future

June 26, 2025

Refrigerant Pump Tech 2025: Innovations & Applications

June 26, 2025In this blog, we compare Hermetically Sealed Pumps and conventional pumps to help industries make an informed choice in 2025. With increasing emphasis on safety, efficiency, and environmental sustainability, hermetically sealed pumps are emerging as a modern alternative to traditional pump technologies. Read on to understand the differences, advantages, and which type best suits your application.

Understanding the Basics

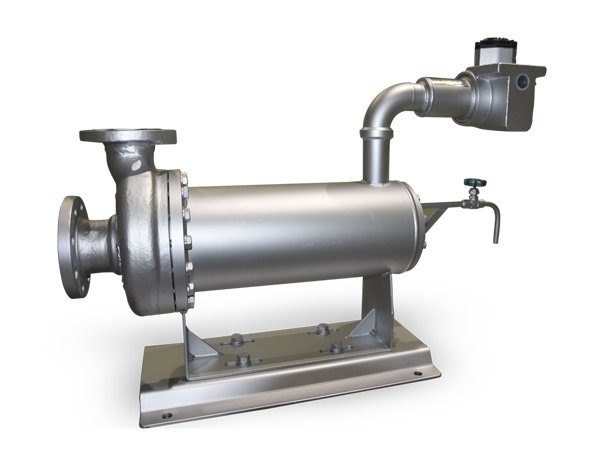

In industrial applications, especially those dealing with hazardous, corrosive, or volatile liquids, pump design plays a critical role in ensuring safety and operational reliability. Conventional pumps, often relying on mechanical seals, have been widely used for decades. In contrast, hermetically sealed pumps, also known as canned motor pumps, eliminate the need for mechanical seals by enclosing the motor and pump into a single, leak-proof unit.

Key Differences Between Hermetically Sealed and Conventional Pumps

1. Leak Prevention

Conventional pumps use mechanical seals which are prone to wear and tear, leading to leaks over time. Hermetically sealed pumps, like those offered by Hydrodyne Teikoku Pump, completely eliminate this risk by using a seal-less design. This makes them ideal for handling toxic, flammable, or environmentally hazardous fluids.

2. Maintenance & Downtime

Mechanical seals require frequent maintenance or replacement. In contrast, hermetically sealed pumps are designed for long-term reliability with minimal maintenance, reducing operational downtime and lifecycle costs.

3. Safety & Compliance

With strict regulations in place for emissions and workplace safety in 2025, hermetically sealed pumps provide a significant advantage. Their enclosed construction ensures compliance with environmental and safety standards, particularly in industries like petrochemicals, pharmaceuticals, and nuclear energy.

4. Operational Efficiency

The integrated design of a hermetically sealed pump reduces energy losses typically caused by shaft misalignment or friction. This contributes to better energy efficiency, which aligns with sustainability goals prevalent across industries today.

5. Cost Implications

While the initial investment in hermetically sealed pumps may be higher than traditional options, the reduced maintenance, longer lifespan, and compliance benefits lead to lower total cost of ownership (TCO) over time.

Why Hydrodyne Teikoku Leads the Way

Hydrodyne Teikoku, a leader in manufacturing Hermetically Sealed Pumps, offers state-of-the-art solutions trusted globally. With decades of engineering expertise and innovation, our pumps are designed for maximum reliability and zero-emission performance, supporting the future of industrial fluid handling.

Conclusion: Which Is Better?

In 2025, hermetically sealed pumps clearly outshine conventional pumps in terms of safety, reliability, and environmental performance. While traditional pumps still have their place in less critical applications, industries focused on hazardous materials, regulatory compliance, and operational efficiency will benefit immensely from making the switch.

FAQs

-

What is a hermetically sealed pump?

A hermetically sealed pump is a type of pump that completely eliminates shaft seals by enclosing the motor and pump in a single, leak-proof housing.

-

Where are hermetically sealed pumps used?

They are widely used in industries like chemical processing, oil & gas, nuclear power, and pharmaceuticals anywhere leak prevention is critical.

-

Are hermetically sealed pumps more expensive than conventional ones?

Initially, yes. However, they offer long-term cost savings due to lower maintenance, zero leakage, and improved efficiency.

-

What makes Hydrodyne Teikoku’s pumps different?

Hydrodyne Teikoku pumps are built with Japanese engineering standards, tailored for high-demand applications with a focus on durability and regulatory compliance.

-

Can hermetically sealed pumps handle high temperatures and pressures?

Absolutely. Hydrodyne Teikoku’s pumps are engineered to handle extreme operating conditions without compromising performance.