Key Facts About the LPA Liquid Refrigerant Pump

September 25, 2025

Top Benefits of Canned Motor Pumps for Industrial Applications

October 24, 2025How KOH Application Pumps Improve Process Efficiency in Manufacturing

Keyword: KOH application pump

There are no more optional aspects of efficiency, precision, and reliability in the systems of a manufacturing company. All aspects are critical! Within the realms of chemical processing, water treatment, food production, and the making of pharmaceuticals, each facility undergoes a ceaseless ‘battle’ to perfect its systems, all while aiming to lower wasted materials and time, and ensuring the best quality of products. New and improved technologies and devices arise and are studied to perfect the current operational model.

Among the technologies, KOH application pumps are gaining great attention and are improving process efficiency and reliability along with the rest of the operational systems.

What Are KOH Application Pumps?

KOH Application pumps are designed to work with the KOH solutions in a safe and effective manner. Potassium Hydroxide is a very caustic chemical and is used in industries for neutralisation, chemical synthesis, and even pH regulation. Any over- or underdosing of KOH can compromise the equipment, the quality of the products, and even cause harm to the entire process. The Application KOH pumps are set to the desired parameters of the device to address all issues of dosing inequities, under- or over-pressure, and flow balance.

The chemical dosing is accurate, repeatable, and automated, thanks to the pumps delivering KOH. This reduces human error and increases reliability in the manufacturing process. Their powerful design also makes them able to survive the corrosive nature of KOH, which makes them ideal for prolonged use in extreme industrial settings.

corrosive nature of KOH makes it suitable for long-term use in demanding industrial environments.

Enhancing Process Efficiency

The process efficacy it provides is perhaps the biggest benefit of a KOH application pump. Manually dosing KOH is inefficient, as operators measure and pour chemicals, and it is incredibly tedious. There is also a chance of a mistake occurring in the process. Even the slightest mistake in the flow or concentration results in a repeat of processing steps, inconsistent product quality, or inefficient overall productivity.

The KOH application pump is capable of continuous and accurate dosing. In chemical production, KOH is used to buffer optimal conditions for higher yield and reduced reaction time due to precision delivery. In water treatment systems, these pumps stabilise the pH levels, preventing pH imbalance at the downstream equipment and avoiding redundant treatment cycles. The outcome is improved operability with less disruption and output consistency.

Key benefits include:

- Consistent chemical flow for predictable reactions

- Reduced human error in dosing

- Optimised use of resources, minimising waste and cost

- Improved reaction speed and yield

Reducing Downtime and Maintenance Costs

Most manufacturing downtimes are challenging, translating to loss of profit and delayed production schedules. Application of KOH pumps minimises this through their ruggedness and reliability. Their construction from anti-corrosive materials means they can endure the extreme corrosive conditions of highly caustic substances. Thus, their durability minimises the chances of pump malfunctions and the consequent maintenance needed, achieving lowered production interruptions.

Increased reliability is evident with KOH pumps that feature self-cleaning systems and easily accessible parts for quick maintenance. Automation further helps reduce the manual handling of the KOH chemical, thereby reducing the chances of slips, leaks, or accidents that would greatly halt the manufacturing process. Therefore, purchasing high-quality pumps has the extra benefits of reduced production interruptions, less maintenance costs and increased control over the manufacturing process.

Supporting Consistency and Quality

During the technological process of production, the stronger the stage of automation, the lower the attention needed for the achievement of the product’s quality. Even small changes in the concentration of KOH might damage a reaction or the properties of the final product. The KOH application pumps guarantee adherence to the scope of work regarding the precision of the poured KOH, thus, every propeller batch produced in the plant is produced in a set or standard and controlled environment, ensuring quality on all production runs.

Why consistency matters?

- Product quality and stability are maintained.

- Customer satisfaction and regulatory compliance are maintained.

- Less rework or batches that are thrown due to errors, and more work is done.

- The entire process is more predictable.

This is true for the chemical producers in the production of soap, where KOH is used, and in other, more complex and complicated chemical production, where the addition of certain chemicals is needed to adjust the pH or neutralise it. The KOH pumps do not work at a certain standard. They work more efficiently and to higher standards than what constant monitoring or manual adjustments would allow.

Safety Considerations

The transfer of chemicals is very sensitive and somewhat dangerous. KOH is very caustic; it can blind or burn someone to a very dangerous extent. People can also spill chemicals if they do not have the proper concentration. KOH application pumps use machinery to transfer and dose chemicals, eliminating the higher-order exposure of people. Many contemporary pumps incorporate additional safeguards, including leak detection, automatic shut-off, and corrosion-resistant construction. These features improve employee and equipment protection, enhancing workplace safety and reducing the likelihood of expensive production halts or associated legal complications.

KOH application pumps also improve the efficiency of chemical management. By dispensing precisely the needed amount of KOH, these pumps help reduce waste, optimise resource usage, and minimise operational costs. Additionally, the discharged KOH legally meets the increasingly stringent environmental regulations, which require manufacturers to control and reduce environmental harm.

Optimising Resource Use and Sustainability

Efficient chemical management is another benefit of KOH application pumps. By delivering only the required amount of KOH, these pumps reduce waste, optimise resource usage, and lower operational costs. Precise dosing also ensures compliance with environmental regulations, which increasingly require manufacturers to monitor chemical discharge and minimise environmental impact.

Resource optimisation highlights:

- Accurate dosing reduces chemical waste and cost

- Supports environmental compliance and sustainability goals

- Minimises unnecessary chemical discharge

- Improves overall process efficiency and profitability

Integration with Modern Manufacturing Systems

Manufacturing is rapidly evolving, with automation and digital monitoring becoming standard. KOH application pumps integrate seamlessly with these systems, including PLCs, SCADA platforms, and other process control technologies. This allows operators to monitor flow rates, chemical usage, and performance in real time, enabling rapid adjustments to maintain optimal efficiency.

Automated monitoring also supports data logging, which provides valuable insights into process efficiency and chemical consumption. These insights can inform better decision-making, facilitate predictive maintenance, and further improve operational reliability. Integration with modern systems ensures that KOH application pumps are not only efficient tools but also valuable components of a fully automated, data-driven production environment.

The Role of Pump Quality

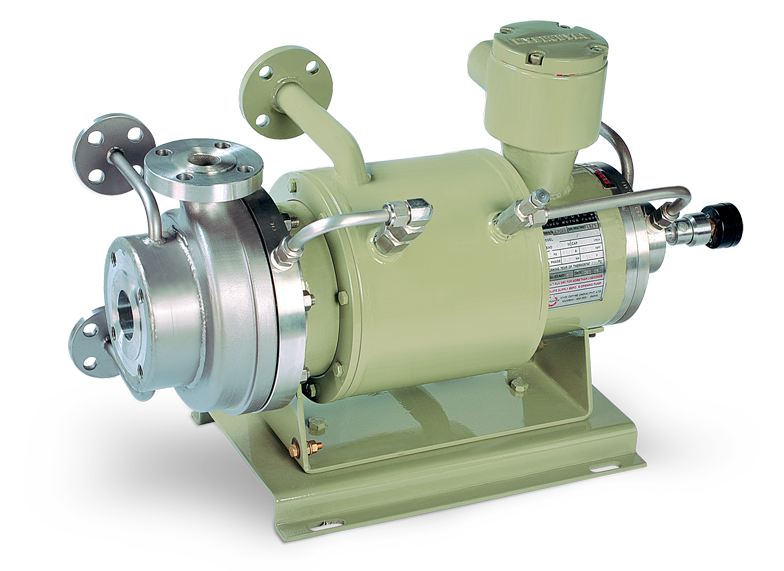

The effectiveness of a KOH application pump is influenced by the pump’s design and construction. Pumps of high quality, for example, Hydrodynepumps, are designed to safely hold and contain corrosive chemicals while being dosed over a long period reliably, and functioning in unstable industrial environments. Leaving funds for a durable and well-designed pump ensures process efficiency is sustained while also protecting the equipment from unplanned downtimes or costly maintenance services.

Real-World Benefits and Applications

In different industries, KOH application pumps have shown improvements in efficiency, safety, and quality by different manufacturers around the world. In chemical plants, reaction times are quicker, waste is reduced, and yields increase. In food processors, ingredients are enhanced while maintaining quality in taste, texture, and overall product. Water treatment plants enjoy stable pH levels while also consuming fewer chemicals that are costly and harmful to the environment.

Applications at a glance:

- Chemical manufacturing: Improved yields and reduced waste

- Food processing: Consistent quality and safety

- Water treatment: Stable pH levels and efficient chemical usage

- General manufacturing: Minimised downtime and operational optimisation

Looking Ahead: The Future of Chemical Dosing

As manufacturing continues to advance, the role of KOH application pumps is set to expand. Smart sensors, AI-driven monitoring, and predictive maintenance will allow pumps to automatically optimise dosing based on real-time process conditions. Integration with Industry 4.0 systems will make chemical dosing smarter, safer, and even more efficient, ensuring that manufacturing facilities remain competitive in an increasingly automated world.

Conclusion

The KOH application pumps are gaining popularity and are vital for the precise dosing of chemicals, manufacturing safety, fewer production downtimes, and enhanced resource optimisation. Automated processes and high reliability make them advantageous for all types of modern industries.

At Hydrodyne Teikoku, we have seen firsthand how our Hydrodynepumps enhance process efficiency, maintain product quality, and support safe and sustainable operations. By choosing high-quality KOH application pumps, manufacturers can achieve operational excellence, reduce costs, and secure long-term success in an increasingly demanding industrial landscape.