Key Features to Look for in Canned Motor Pumps from Indian Manufacturers

August 26, 2024

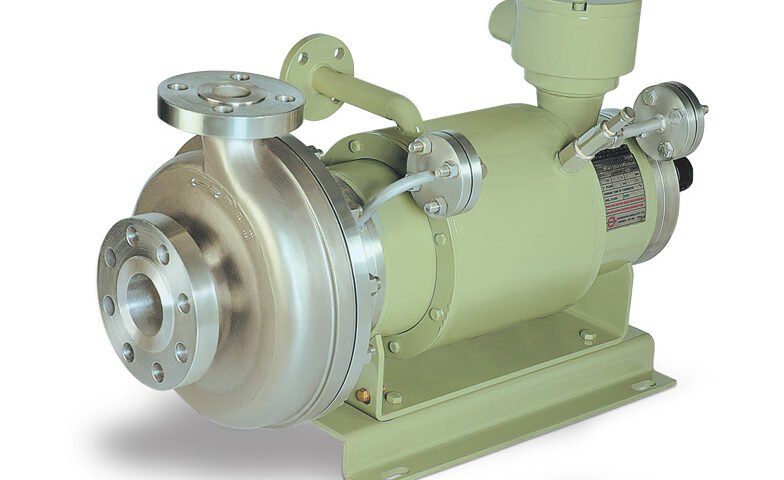

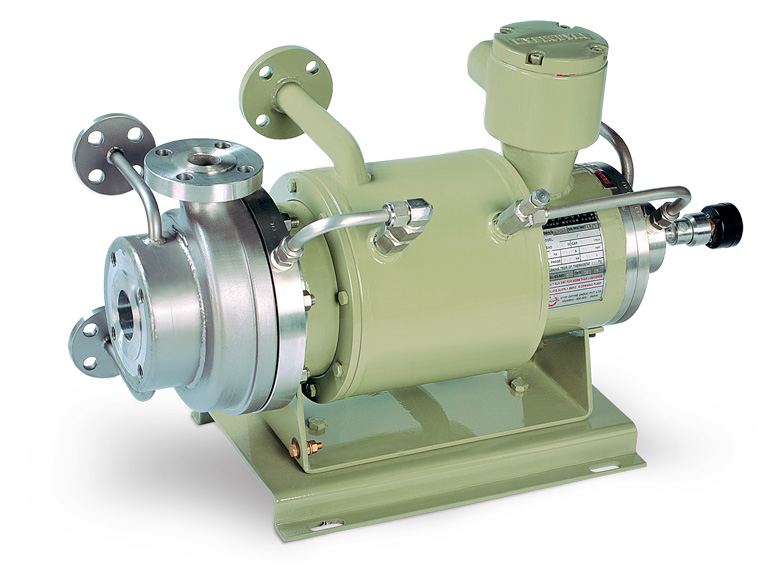

Top 5 Advantages Of Using Centrifugal Canned Motor Pumps In Industrial Applications

September 23, 2024Canned motor pumps have been around serving different industries for many years because of their effectiveness and durability, not forgetting the requirement of little or no exercise of maintenance. The industries of various locations in India are still in the process of developing, and hence, there is a need for advanced technology in pumps. Hydrodyne Teikoku India Pvt. Ltd., one of the leading companies in this sector, has been a pioneer in bringing out new concept solutions to Canned Motor Pumps In India, which cater to the needs of the Indian market.

The Evolution of Canned Motor Pumps

Canned motor pumps that are sealless in design have experienced improvement in their design in recent years. These pumps do not use any mechanical seals for operation, and that is the leading cause of failure for most pumps. The outcome is a more efficient and leak-free system that is perfect for working with dangerous or valuable liquids. With the influx of industries, especially chemicals, pharmaceuticals, and power generation in India, there has always been a need to produce high-performance, maintenance-free pumps, which is the reason for such innovation.

Energy Efficiency: A Key Focus

Energy efficiency is one of the main areas where researchers and engineers have achieved a significant step forward with Canned Motor Pumps In India. Concerns about high energy costs still hurt the Indian industries; however, the advanced canned motor pumps are equipped to cut down energy expenses substantially. These pumps have subsequently improved efficiency through better-situated motor design and the use of higher-quality materials; hence, overall operational costs have been reduced, and pollution has been minimized.

Enhanced Durability and Reliability

Industry in India is characterized by some unfavorable conditions, in that customers expect the equipment to withstand rugged operating conditions and be frequently used. New trends in canned motor pumps have emerged in the past years in terms of developing long-lasting and dependable pumps. The latest technologies are being incorporated into the manufacture of pumps, including the use of advanced materials like corrosion resistant alloys and high-performance ceramics, which help increase the working life of the equipment. Also, enhanced cooling systems have been incorporated to deal with heating issues much better so as to allow the pumps to run persistently without overheating or failure.

Advanced Monitoring and Control Systems

Canned motor pump advancement proves that the incorporation of intelligent technology is the following remarkable evolution. Today, pumps incorporate electronics that include monitoring and controlling devices that enable the tracking of their activity. These systems are useful in detecting early problems before they reach advanced levels where they cause huge problems, and this leads to the prevention of huge problems or breaks that would require system downtime.

To Indian industries where operational emissions are of great importance, these intelligent pumps are a great choice because they offer control and monitoring like nothing has been done before.

Compliance with Indian Standards

The usage of the technology under consideration has to adhere to local requirements and practices in the Indian industries. Modern advancements in canned motor pumps have been made with significant consideration of such needs. These pumps are manufactured to be efficient and comply with the regulatory authority of Indian laws to be safe to use and meet the standards. This focus on compliance established them as a preferred solution in different industries across the country, especially in industries that require safety and environmental strategies.

Customisation for Indian Applications

The growth factor that has been observed in the canned motor pump market is the factor of customisation. Cognizant of this reality, some manufacturers of pumps, such as Hydrodyne Teikoku India Pvt. Ltd., have been developing pumps, especially for particular sectors, as mentioned below. These specific pumps are designed with specific requirements, whether it is the flow rate, the temperature or the chemical compatibility of the fluid to be pumped, so there is always one pump per application. Flexibility is highly beneficial, especially when it comes to a market such as India, which has been characterized by the diverse needs of different industries.

Conclusion

The current condition of Canned Motor Pumps In India is growing quickly and constantly demands better, more reliable, and technologically superior products. Advancements in this industry are not only satisfying these requirements but are going a step further, even offering better solutions. Since industries across the country are growing and modernizing, the importance of advanced canned motor pumps will continue to rise. Hydrodyne Teikoku India Pvt. Ltd., with its emphasis on advanced technology and solutions tailored to the market, is ideally placed to drive this change, providing the Indian industries with the equipment they require to succeed as players in the global economy.