What Is a Hermetically Sealed Canned Motor Pump?

February 2, 2026

High Temperature Pumps in 2026: Applications, Materials, and Selection Guide

February 2, 2026As industrial processes become more demanding in terms of safety, efficiency, and chemical compatibility, the role of specialized pumping solutions has never been more critical. Among these, KOH pumps continue to hold a vital position in industries that handle potassium hydroxide and other highly corrosive alkaline fluids. In 2026, advancements in materials, design engineering, and operational monitoring have further strengthened the reliability and performance expectations from KOH pumps.

At HydrodynePump Teikoku, with over two decades of experience in manufacturing high-performance canned motor pumps, we understand that pumping potassium hydroxide is not just about fluid transfer it is about safety, precision, and long-term operational stability.

This blog explores the applications of KOH pumps, key selection considerations, and best maintenance practices relevant for modern industrial operations.

Understanding KOH Pumps and Their Industrial Importance

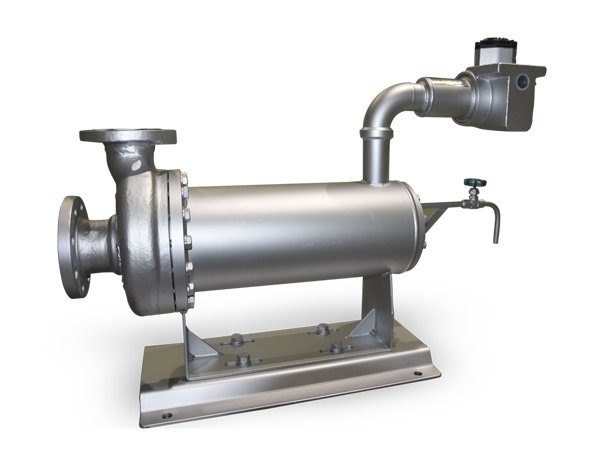

KOH pumps are designed specifically to handle potassium hydroxide (KOH), a highly corrosive, hygroscopic, and chemically aggressive alkali widely used in industrial processes. Due to its corrosive nature, conventional pump designs with mechanical seals and standard materials often face premature failure, leakage risks, and high maintenance costs.

In response, industries increasingly rely on seal-less pump designs, such as canned motor pumps, for KOH service. These pumps eliminate external leakage points and ensure safe, reliable operation even under continuous and demanding conditions.

Key Applications of KOH Pumps in 2026

The use of KOH continues to expand across multiple sectors, driving steady demand for specialized KOH pumps that can operate safely and consistently.

Chemical Processing Industry

KOH is extensively used in chemical manufacturing for neutralization reactions, catalyst preparation, pH control, and specialty chemical synthesis. In these applications, KOH pumps must withstand corrosive exposure while maintaining consistent flow rates and pressure.

Pharmaceutical & API Manufacturing

In pharmaceutical production, potassium hydroxide is used for synthesis, cleaning processes, and formulation control. Here, KOH pumps must ensure contamination-free operation, precise dosing, and high reliability to meet stringent quality and compliance standards.

Battery & Energy Storage Manufacturing

With the growth of alkaline batteries and energy storage technologies, KOH plays a critical role as an electrolyte. KOH pumps in this sector are expected to deliver high purity handling, leak-free performance, and compatibility with cleanroom or controlled environments.

Textile & Pulp Processing

KOH is used in textile treatment and pulp processing for bleaching and fiber preparation. Pumps operating in these industries must tolerate continuous operation and fluctuating process conditions without corrosion-related failures.

Food & Industrial Cleaning Applications

Although used in controlled concentrations, KOH is employed in industrial cleaning, CIP systems, and food-grade processing equipment. Reliable KOH pumps help maintain safety and hygiene while preventing accidental exposure.

KOH Pump Selection Guide: What to Consider

Selecting the right KOH pump is critical to both safety and lifecycle cost optimization. In 2026, procurement and engineering teams focus on the following key criteria:

1. Material Compatibility

Material selection remains the most important factor. Wetted components must resist strong alkaline corrosion. High-grade stainless steels, special alloys, and non-metallic linings are commonly used depending on concentration and operating temperature.

Canned motor pump designs further enhance protection by isolating critical motor components from chemical exposure.

2. Seal-less Design for Safety

Because KOH is hazardous, eliminating leakage risk is essential. Seal-less KOH pumps, such as canned motor pumps, are preferred for their hermetically sealed construction, ensuring zero external leakage during operation.

3. Operating Conditions

Flow rate, pressure, temperature, and KOH concentration must be clearly defined. Pumps must be engineered to handle both steady-state operation and transient conditions without cavitation or performance loss.

4. Energy Efficiency

Energy efficiency is a growing priority in 2026. Efficient motor design, optimized hydraulics, and reduced mechanical losses directly impact operating costs over the pump’s lifecycle.

5. Maintenance & Lifecycle Costs

Beyond initial procurement, decision-makers increasingly evaluate total cost of ownership. Pumps with fewer wear parts, lower maintenance frequency, and longer service intervals deliver measurable long-term value.

Maintenance Best Practices for KOH Pumps

While modern KOH pumps are designed for durability, proper maintenance remains essential for optimal performance and longevity.

Routine Operational Monitoring

Operators should regularly monitor vibration levels, temperature, and power consumption. Any deviation from baseline performance can indicate early wear or process issues.

Fluid Quality Control

Impurities, solids, or crystallization in potassium hydroxide can accelerate wear. Ensuring proper filtration and maintaining consistent concentration levels helps protect internal pump components.

Cooling & Lubrication Checks

In canned motor KOH pumps, the process fluid often plays a role in cooling and lubrication. Maintaining correct flow paths and preventing blockages is critical for motor health.

Scheduled Inspections

Although seal-less designs reduce maintenance, periodic inspections of bearings, electrical parameters, and hydraulic components help prevent unplanned downtime.

Documentation & Predictive Maintenance

Modern plants increasingly integrate KOH pumps into digital maintenance systems. Tracking operating data over time enables predictive maintenance strategies that reduce risk and improve uptime.

KOH Pumps in 2026: A Strategic Asset

In today’s industrial landscape, KOH pumps are no longer just supporting equipment they are strategic assets that influence plant safety, efficiency, and compliance. As potassium hydroxide continues to play a key role across industries, the demand for reliable, leak-free, and application-specific pumping solutions will only increase.

At HydrodynePump Teikoku, our expertise in engineered canned motor pump solutions allows us to support critical KOH applications with precision-built designs that prioritize safety, durability, and operational excellence.

By choosing the right KOH pump and following best-practice maintenance strategies, industries can achieve long-term reliability and confidence in even the most demanding alkaline service conditions.