Top 5 Applications For Multistage Canned Motor Pumps

June 11, 2024

Advantages Of Using Sealless Canned Motor Pump

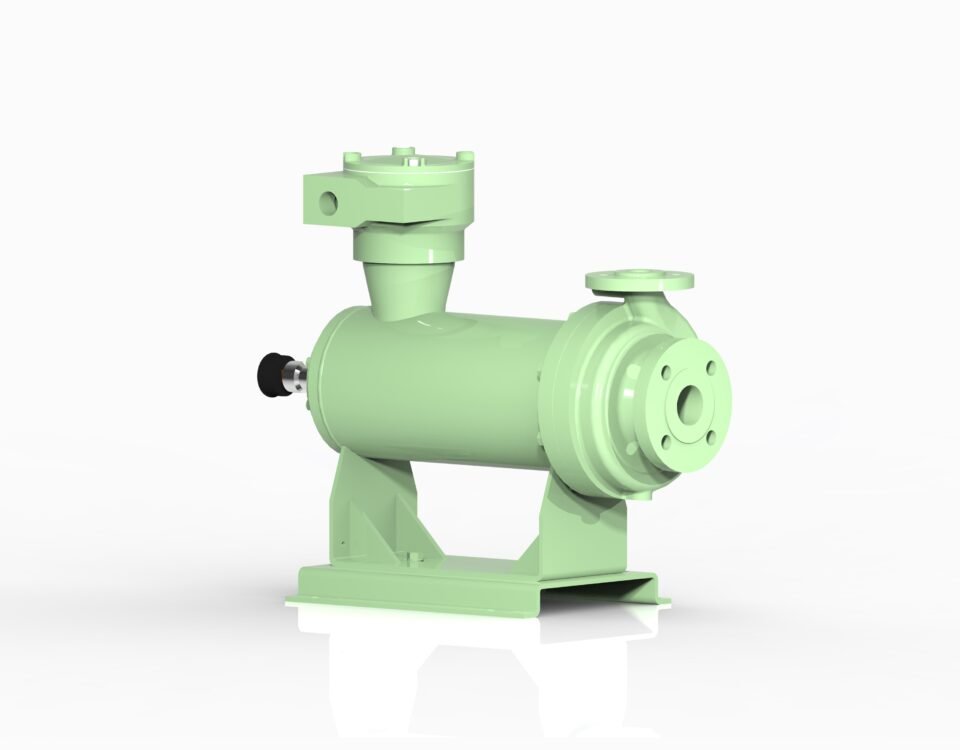

June 15, 2024Heavy-duty industries that deals with hazardous and dangerous fluids often look out for the pumps that provides them with total leakage-free handling. When it comes to safety, efficiency, and reliability then Canned Motor Pumps becomes an ideal choice. The motor pumps with API 685 tick all your requirement boxes.

Numerous chemical industries also carry out transportation activities that include transfer of fluids from one place to another. This activity requires a complete security and that is only assured through canned motor pumps. If your company hasn’t yet installed these pumps, then you must read this article which will provide you with all the reasons on why you should use canned motor pump in a chemical industry.

Reasons to use Canned Motor Pumps in Chemical Industry:

-

Leak-free operation:

The primary feature that a canned motor pump provides to any industry is leak-free operation. Leakage prevention is very crucial, especially when it comes to the chemical sector, as the fluids or chemicals they use are harmful and can cause health issues to the surrounding individuals. Acids, Benzene, and alkali are some of the common materials used in the chemical industry. These chemicals hold a high level of risk and thus need to be stored and protected. Thus, CMPs assist these industries from harmful emissions and keep hazardous substances away from the environment.

-

Enhanced Safety:

Safety is a priority in chemical industries. Toxic, harmful, and poisonous gases or fluids are to be kept safe from humans and while doing so, Canned Motor Pumps play a pivotal role. With fewer mechanical components and robust materials, these pumps assure and enhance safety. They are ideal for handling fluids and chemical gases and thus have been given the API 685 standards. The pumps are perfectly fitted to hold or transfer any kind of chemicals.

-

Low Maintenance:

In the chemical industry, operations require a lot of effort and money. As the industry deals with dangerous and harmful fluids, they choose equipment that is totally safe and convenient, even if it costs them a little extra. However, canned motor pumps can take up the responsibility of the handling sector in the industry. Due to the materials and sealless mechanisms, these pumps enjoy a long life operation. They also have the inbuilt tracking system which detects any future issues or malfunctions, ultimately reducing the maintenance time and cost.

-

Durability:

Durability is another benefit that a canned motor pump provides. It is totally different from the traditional pumps that have mechanical seals not ideal for preventing leakage. Canned motor pumps have the capability to operate for a long period due to low maintenance costs and comparatively rigorous materials. Chemical industries include operations that are dangerous and require a lot of effort. This can be eased down with the help of Canned Motor Pumps.

-

Compliance with regulatory standards:

The canned motor pumps operate under API 685 standards, which provides its users with quality assurance. Canned motor pumps have been given these standards by precise testing. Materials, quality, cost, performance, and reliability of the pumps are the factors considered when allocating them as the hallmark. Due to this, canned motor pumps are an ideal choice for the chemical industry, which requires extra protection for the fluids. Its operations adhere to the high industry standards.

Conclusion

There are numerous pumps out there, but chemical industries still prefer canned motor pumps due to their robust materials, quality services, high-temperature tolerance, reduced vibration and noise, and superior reliability.

Hydrodyne Teikoku Pumps come up with canned motor pumps that provide you with all the qualities mentioned above. You can always opt for this pump when dealing with dangerous or harmful fluids to ensure smooth and safe operations.