Understanding Flow Rates and Efficiency in Sealless Canned Pumps

November 29, 2024

Factors to Consider When Installing an Industrial Pump and Motor System

December 1, 2024KOH pumps are required to deal with potassium hydroxide, an extremely reactive and caustic chemical essential in much industrial processing. Safety and efficiency pumps will help streamline activity from chemical production to renewable energy systems. This guide looks at the functionality of the KOH Pumps, applications, and benefits while emphasizing their critical role in industrial processes.

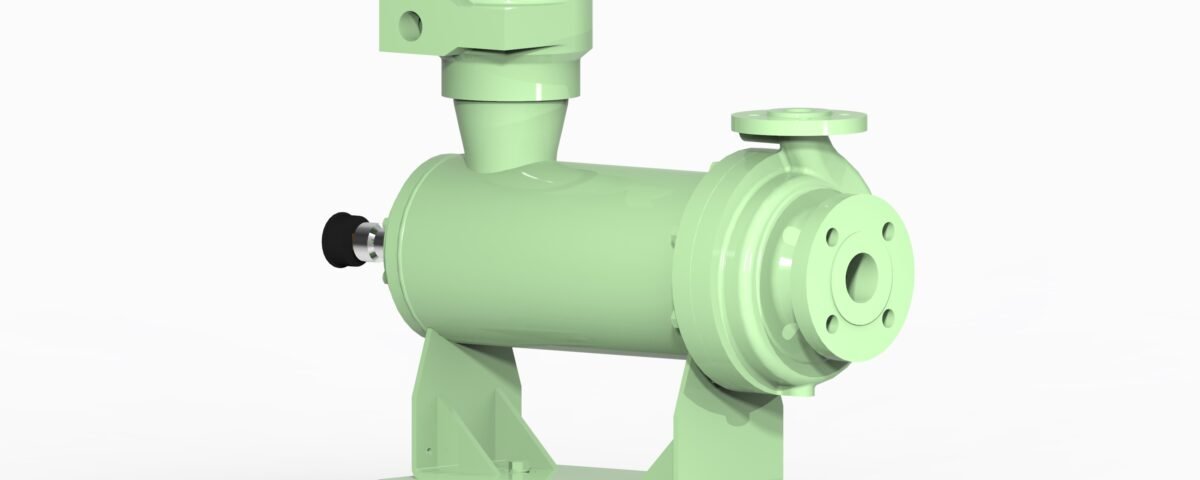

What Are KOH Pumps?

KOH pumps are specialized equipment for managing potassium hydroxide in a controlled manner. Potassium hydroxide is widely used in soap manufacture, biodiesel production, fertilizer, and water-treatment acid meant to regulate pH. This chemical is highly corrosive. Therefore, these pumps are created using solid materials and advanced features to survive in the toughest environment with assured safety and accuracy in industries.

Advanced Features of KOH Pumps

Modern KOH pumps are designed with capabilities that give them a longer lifespan and better work. Some attributes include using corrosion-resistant materials like stainless steel or high-grade polymers, leak-proof mechanisms such as a magnetic drive system, and high flow efficiency for optimized operations. Many pumps come as customizable; industries could tailor the pump to specific process requirements.

Applications Across Diverse Industries

KOH pumps are versatile and used across a variety of industries:

- Chemical manufacturing: Assists in the manufacture of cleaning agents, soaps, and industrial chemicals.

- Water treatment: Assists in maintaining pH and to neutralize acidic waste.

- Biodiesel: KOH plays a very crucial role as a catalyst in producing biodiesel.

- Pharmaceuticals: Assists precision handling of chemicals in drug production.

- Agriculture: Assisted in fertilizer production and precise delivery of dosages of chemicals.

Benefits of KOH Pumps in Industrial Use

With all these applications, the KOH pump has numerous benefits that make it an important tool during industrial usage:

- Enhanced safety through leak-proof designs and robust materials.

- Operational efficiency, reducing energy costs, and improving productivity.

- Environmental sustainability by preventing hazardous leaks and ensuring compliance with safety standards.

- Long-term cost savings through reduced maintenance and increased durability.

Tips for Choosing the Right KOH Pump

The right KOH Pump, considering chemical compatibility, desired flow rate and pressure, durability, and easy incorporation, must be selected. The pumps, thus, should meet the application’s specific needs to ensure smooth and efficient operations. Therefore, by consulting experts involved in the selection process, businesses help choose the best equipment for any operation.

Maintenance Practices to Extend Pump Lifespan

Regular maintenance will prolong the life and performance of KOH pumps. Routine inspections, cleaning of parts to prevent chemical buildup, and monitoring of operational parameters are all significant practices. Proper training of personnel in regard to the safe handling of potassium hydroxide and maintenance of the equipment will create more efficiency and safety in its functionality.

Sustainability and Future Trends for KOH Pumps

The future of KOH pumps is in terms of sustainability and innovation. The rapidly enhanced importance of going green within industries has advanced pump technology into a future that consumes energy and negatively impacts the environment. New materials and designs are surfacing, furthering safety and efficiency in these pumps and guaranteeing they will be in solidarity with today’s processing requirements.

Processes Optimized by KOH Pumps

KOH pumps will not only counter the difficulties arising from handling potassium hydroxide but also process optimization. Consistent flow rates plus no occurrence of downtime ensures a general increase in the productivity and efficiency of industrial systems that depend on them. Their superior adaptation to stiff conditions makes it easier for business entities to enjoy improved performance without huge risks.

Conclusion

KOH Pumps might be more than a tool for potassium hydroxide; they are the key to efficiency and safety in most industrial processes. These pumps deliver unrivaled reliability and performance from chemical manufacturing to water treatment. With proper maintenance and selection, businesses will unlock full power from the KOH pump, enhancing their operations’ productivity, safety, and sustainability. In years to come, these pumps will continue to revolutionize how industries handle their critical processes.