How To Select The Right API 685 Canned Motor Pump For Oil and Gas Production

June 21, 2024

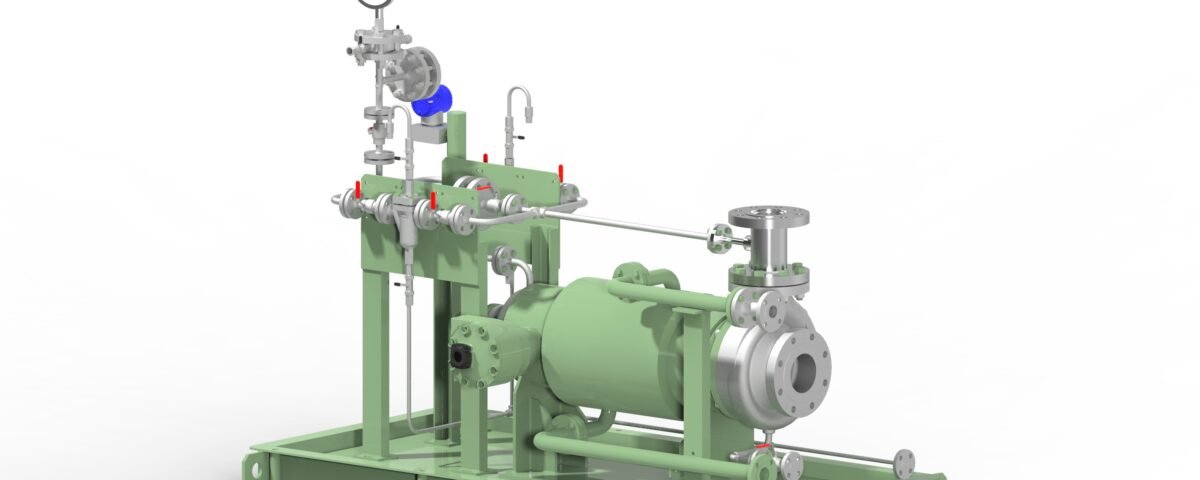

Revolutionizing Industrial Processes: The Advantages of Hermetically Sealed Canned Motor Pumps

August 5, 2024Maintenance is an important activity that has to be performed to carry out the operations smoothly. Be it any machine, maintenance is required for its sustainable performance. Similarly, Centrifugal Canned Motor Pumps need maintenance for the work to go efficiently and effectively.

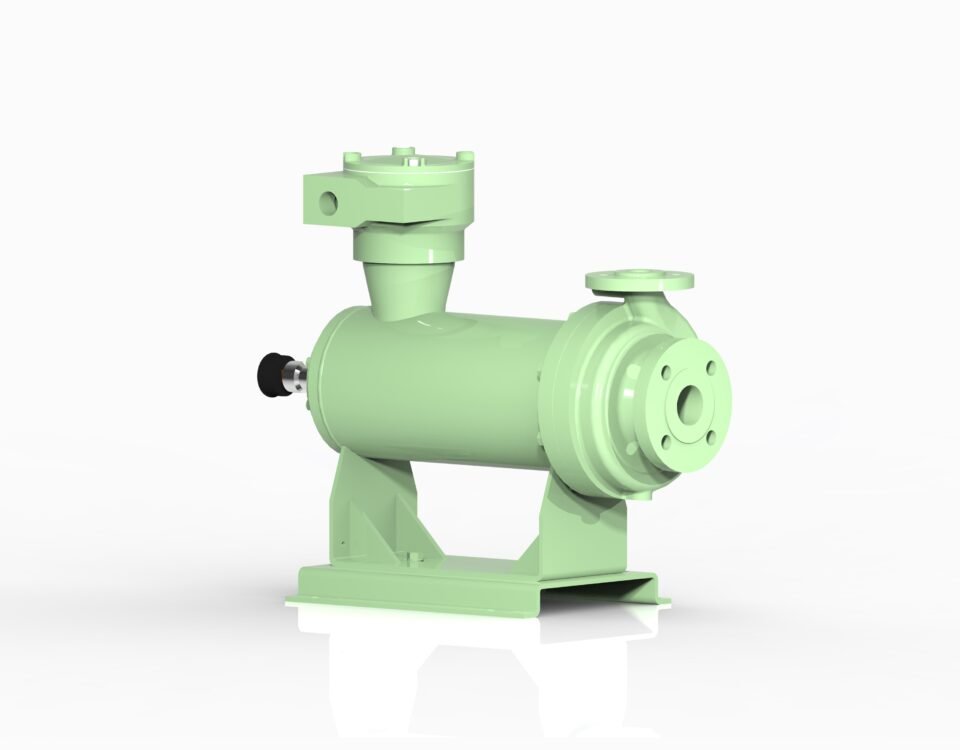

As sealless canned motor pumps are constructed with robust materials and have fewer technical components compare to the traditional pumps, they require less maintenance. In this article, we will suggest some tips for maintaining the centrifugal canned motor pumps and how one can do it to carry out their work efficiently.

Tips for Maintaining Centrifugal Canned Motor Pumps

- Regular inspection:

Inspecting overall work of the canned motor pump is very crucial and the first step to do in maintenance. The industry using centrifugal canned motor pumps need to check the pumps regularly to get the clarification of any breakage, leakage, seepage, corrosion, etc. Inspecting can be helpful in lowering the risk of significant problems in the future.

- Performance Monitoring:

This activity is somewhat similar to the inspection session. The pump’s performance can only be tracked after precisely examining its workings. Always monitor the centrifugal canned motor pumps’ flow rate, pressure, and temperature. However, the API 685 Hydrodyne canned motor pumps come with in-built sensors and monitors such as E-bearing monitors. This not only helps to monitor running clearance but also detect any potential risks.

- Seal maintenance:

Seal inspection is also necessary to check for any signs of breakage or leakage. However, the Hydrodyne canned motor pumps come up with a sealless design and thus have less risk than traditional or mechanical seal pumps. Sealless design pumps are considered the best, and thus, we recommend you to choose Hydrodyne canned motor pumps which have this quality. If a problem still arises related to the seal of the pump, then replace it as soon as possible.

- Motor protection:

The motors of the Centrifugal Canned Motor Pumps that regulate all operations need to be checked thoroughly to ensure that they are in good working condition. Circuit breakers and thermal overload relays are some of the motor protection devices of canned motor pumps that help protect from electrical faults. The motor should be working accurately for smooth and safe operations.

- Scheduled maintenance:

Just as you maintain your company or industries regularly, centrifugal canned motor pumps require regular maintenance too. Schedule maintenance with your manufacturer every month or once in two months to make sure all the components are working properly. Hydrodyne canned motor pumps provide its users with the advantage of less maintenance cost and time due to the absence of mechanical seals.

Safety Precautions to be taken for maintaining Canned Motor Pumps

- Follow chemical safety protocols:

As centrifugal canned motor pumps are used to handle hazardous fluids, one must follow all safety protocols. To ensure the pumps work smoothly, the accurate temperature, appropriate amount of fluids, and proper ventilation should be set.

- Mechanical safety:

Ensure that all the mechanical components and moving parts of the pumps are entirely stopped before starting maintenance. This process is done to promise the mechanical safety of the centrifugal canned motor pumps.

- Emergency shutdown procedures:

In case of any emergency, like fire, chemical spill, machine failure, etc, one must know how to safely close down these motor pumps without damaging them.

Conclusion

Maintaining Centrifugal Canned Motor Pumps can be a daunting task, but if taken from the right manufacturer like Hydrodyne Teikoku Pumps, one can ease down this pressure. The company specializes in manufacturing canned motor pumps. Their pumps are made of materials that require less maintenance.

Hydrodyne Teikoku Pumps also helps you with scheduled maintenance of the canned motor pumps at an affordable price. They offer you complete mechanical and electrical safety that won’t disrupt your industry operations.