Top Applications for Sealless Canned Motor Pumps in Various Industries

August 20, 2024

Choosing the Right Seal-Less Pump: A Guide for Different Needs

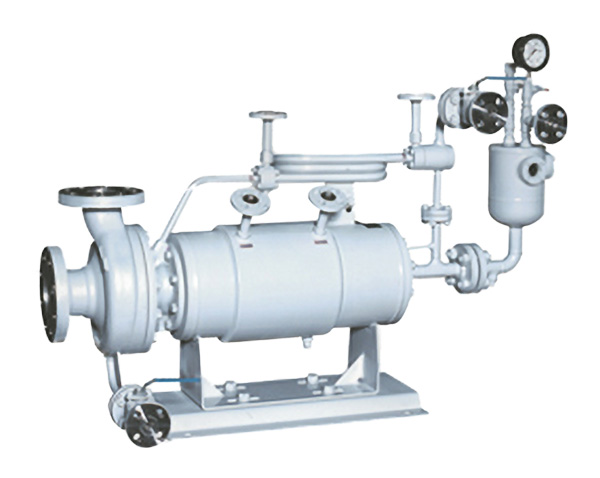

August 22, 2024Sealless Canned Pumps are considered one of the innovative products in fluid handling systems due to their leak-free and low maintenance requirement, which is widely demanded by various industries. These pumps, which feature a lightweight structure and high efficiency, do not involve mechanical seals, thus avoiding the occurrence of leaks and related maintenance expenses. Hydrodyne Teikoku India Pvt. Ltd., which specializes in manufacturing Sealless Canned Pumps, offers solutions for diverse industries.

1. Chemical Processing Industry

Within the chemical processing industry, corrosive and hazardous fluids are constantly handled. Sealless canned type is well suited to this industry because the pumps can handle aggressive chemicals without any leakage. The lack of seal lubrication means toxic and corrosive fluids are not released into the environment, making workers safe. These pumps are also corrosive, hence serving their customers a holistic package for corrosive chemical working conditions.

2. Petrochemical Industry

The petrochemical industry encompasses the use of flammable and explosive hydrocarbons and hence calls for the use of optimum and efficient pumps. Sealless canned pumps are suitable for transferring different kinds of petroleum products since they do not use mechanical seals, which can cause leakage and explosions. Because they are capable of functioning excellently under high temperatures and pressures, their usage in petrochemical-related systems must be considered.

3. Pharmaceutical Industry

When it comes to a pharma company’s product quality, purity is the central concern. Sealless canned pumps are used in conventional systems because they help protect fluids from being transferred in cans and ensure they are not contaminated. These pumps are primarily applied in processes where issues of sterility or cleanliness are strictly considered, for instance, in the production of vaccines and antibiotics, among other pharmaceuticals. Lack of seals also cuts across the possibilities of contamination, which claims sealless canned pumps are the best in the pharmaceutical manufacturing companies.

4. Nuclear Power Plants

Sealless canned pumps have also been applied in nuclear sites where the safety and performance of the system are the top most priorities. These pumps are used in the circulation of coolants and other fluids as well as in essential processes that require no leakage. The sealless design aims to minimize the leakage of radioactive fluids with potential exposure. Due to their capacity to transport high-pressure and high-temperature fluids, they are suitable for use in nuclear facilities that tend to present several challenging conditions.

5. Oil and Gas Industry

In the oil and gas industry, there is a need for pumping solutions that work well in very harsh environments, such as offshore and onshore drilling. Sealless canned pumps are well adapted to this industry because of their ruggedness and capabilities to work in hostile conditions. They are widely applied in carrying crude oil, natural gas, and other hydrocarbons, so leakage prevention is vital. The reliability of Sealless Pumps in handling abrasive and corrosive fluids makes the operations to be free and constant, thus reducing the frequency of replacements.

6. Food and Beverage Industry

Hygiene and safety are very crucial factors that are perfectly implemented in the food and beverage industry. Sealless canned pumps are employed to transport liquids such as juices, syrups and milk products without getting contaminated. The lack of a seal permanently eliminates the chances of complications and makes it possible for the products to stay safe for human consumption. Moreover, they can be easily cleaned, and the fact that they require cleanability makes these pumps appropriate for the food processing industry.

7. Water Treatment Plants

Sealless canned pumps are used at various stages of water treatment and purification, as well as water wastage management, including the treatment of wastewater. These pumps deal with chemicals like chlorine, acids, and alkalis, which play crucial roles in the treatment procedure. Sealless Pumps are designed in such a way that they do not release any form of chemical into the environment; hence, they safeguard the environment and the health of the public. They are durable gears with high levels of resistance to corrosion; hence, they are suitable for prolonged use in water treatment plants.

Conclusion

Sealless Canned Pumps are indispensable in many industries because of their closed structure, good performance characteristics, and adaptability to work with various fluids. They are used in chemical processing, petrochemical industries, pharmaceutical industries, nuclear power plants, etc, as these offer an efficient way to transfer fluids safely. Hydrodyne Teikoku India Pvt. Ltd. deals with sealless canned pumps that can fulfill the functions of the above industries since they can perform excellently and safely to suit every task.